7

®

CAT2TLL - CAT25TL - v1.1 - 02012014

EN

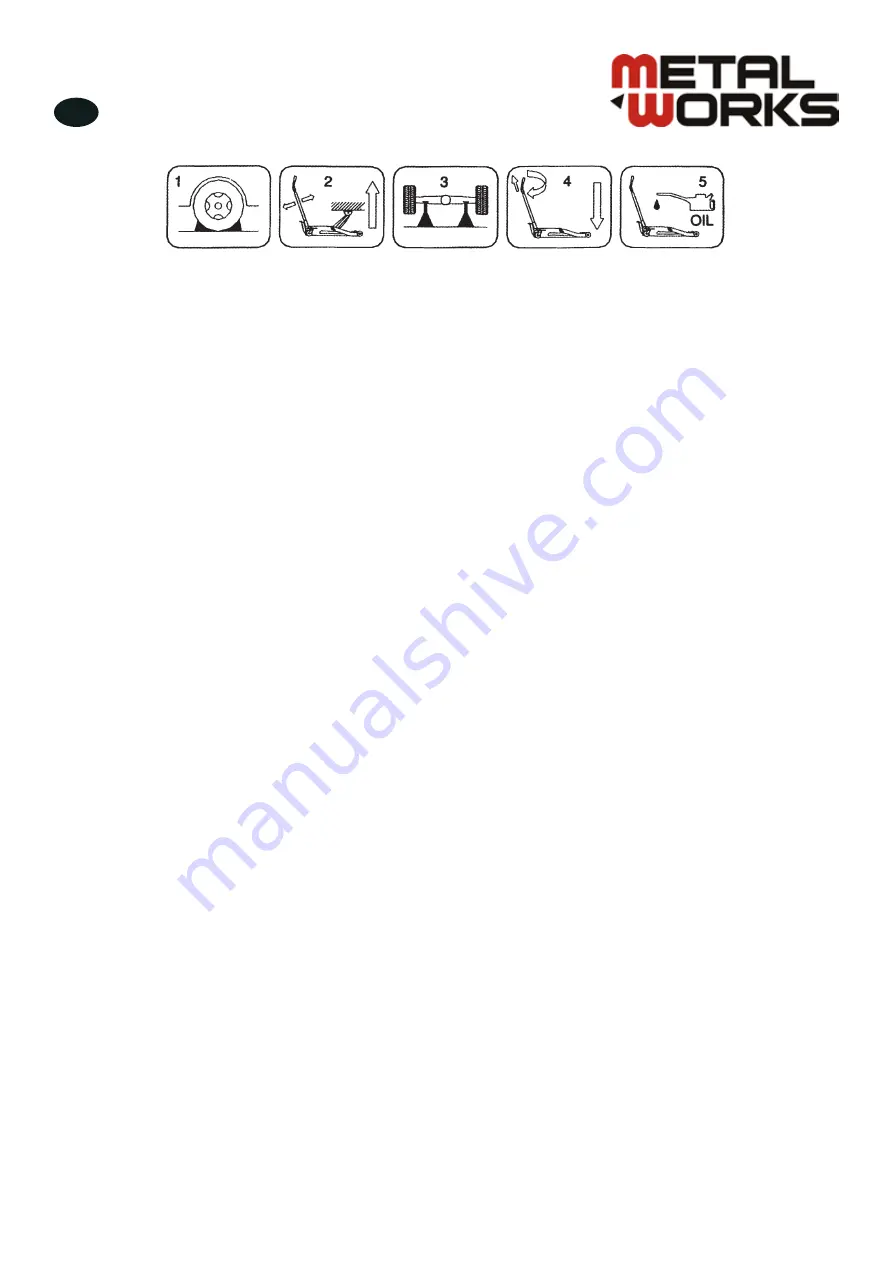

Maintenance

• When not in use the lifting arm and pump lever should be fully in the down position.

• Regularly check the oil level (5):

- Place the jack on an even level surface.

- Open the release valve.

- The correct oil level is at the bottom of the thread inside the oil chamber when the lifting arm is at it’s fully down

position.

- If lacking oil, remove the vent plug located under the cover, fill with good quality blended jack oil (SAE10) to the

correct level, replace and tighten the vent plug.

- Raise the lifting arm up to it’s full height and then open the release valve; step on to the saddle and force the lifting

arm down as rapidly as possible. Repeat three to four times to ensure complete distribution of the oil.

- Close the release valve tightly and check that the jack works correctly under load.

• Keep the jack clean, dry and ensure all moving parts are well lubricated using a light oil, lubricate the handle socket

and lifting arm with a suitable grease.

• Grease the lift arm pivot using the grease nipple provided.

• Should any part require replacement through normal use contact your Metalworks stockist for spare parts.

• Before use check the jack for any signs of missing parts, cracking, damage or distortion - do not use if any damage

is found. Do not modify this product in any way.

copyrighted

document

- all

rights

reserved

by

FBC