Page

25

of

64

3.3 Spraying

Follow the below procedure to commence spraying:

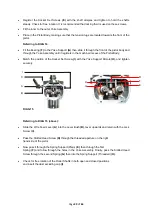

Once lit, if fitted adjust the spreader, in the direction shown below to give the desired

direction of the spread.

NOTE

: There is a position of the spreader where the air to the spreader jet is cut off. If the

spreader is not required, rotate the spreader until it shuts off.

WARNING

: The Spreader should always be turned in an anti-clockwise direction

(from operator point of view). Rotating in a clockwise direction (from an operator

point of view) could loosen air cover, potentially resulting in damage being caused.

Point the pistol at the prepared

work and maintain a spraying

range of approximately 6”

(150mm).

Increasing

spray

distance will dramatically reduce

efficiency.

In even sweeping movements

to cover the area required and

repeat

until

the

desired

thickness is achieved.

Keep the pistol as close to 90°

to the spray surface as possible,

and no more than 45° from

perpendicular.

See

left

illustration for an example of

this.

NOTE:

By changing spray angle you will affect the coating quality and spray efficiency.

NOTE:

Whilst spraying air may be expelled from the

Cam Spindle Housing. This is normal and

aids the cleaning of the valve area.

Operator Point of View

Summary of Contents for MK 73

Page 1: ...Page 1 of 64 ssue 21 11 11 ...

Page 43: ...Page 43 of 64 SECTION 5 FAULT FINDING 5 1 Troubleshooting 5 1 2 Flowmeter Troubleshooting ...

Page 58: ...Page 58 of 64 SECTION 8 INFORMATION TABLES 8 1 Flowmeter Settings 8 2 Nozzle Selection Chart ...

Page 61: ...Page 61 of 64 Notes ...

Page 62: ...Page 62 of 64 ...

Page 63: ...Page 63 of 64 ...