6

SSG 16 | Version 2.01

Technical Data

3.1 Residual risks

Even if all safety regulations are observed and the ma-

chine is used correctly, there are still residual risks listed

below:

- Pinching of body parts.

- Injuries from flying workpieces or workpiece parts.

- Danger of breakage of the tool.

4

Technical Data

4.1 Table

5

Transport, package and storage

5.1 Delivery and Transport

Check the machine on delivery for any visible transpor-

tation damage. If you notice any damage to the device

please report this immediately to the carrier or dealer.

5.2 Packaging

All packaging materials and packing aids used for the hy-

draulic workshop press are suitable for recycling and

must always be disposed of using material-based recy-

cling systems.

Packaging materials made of cardboard must be shred-

ded and disposed of as part of waste paper recycling.

The foils are made of polyethylene (PE), padding is

made of polystyrene (PS). Dispose of these at a recy-

cling center or hand them over to the relevant waste dis-

posal company.

5.3 Storage

Store the device in a dry, clean, dust-free and frost-free

environment. It must not be placed in a room with highly

oxidising chemicals.

Also, all bare metal parts must be greased against corro-

sion.

6

Description of the device

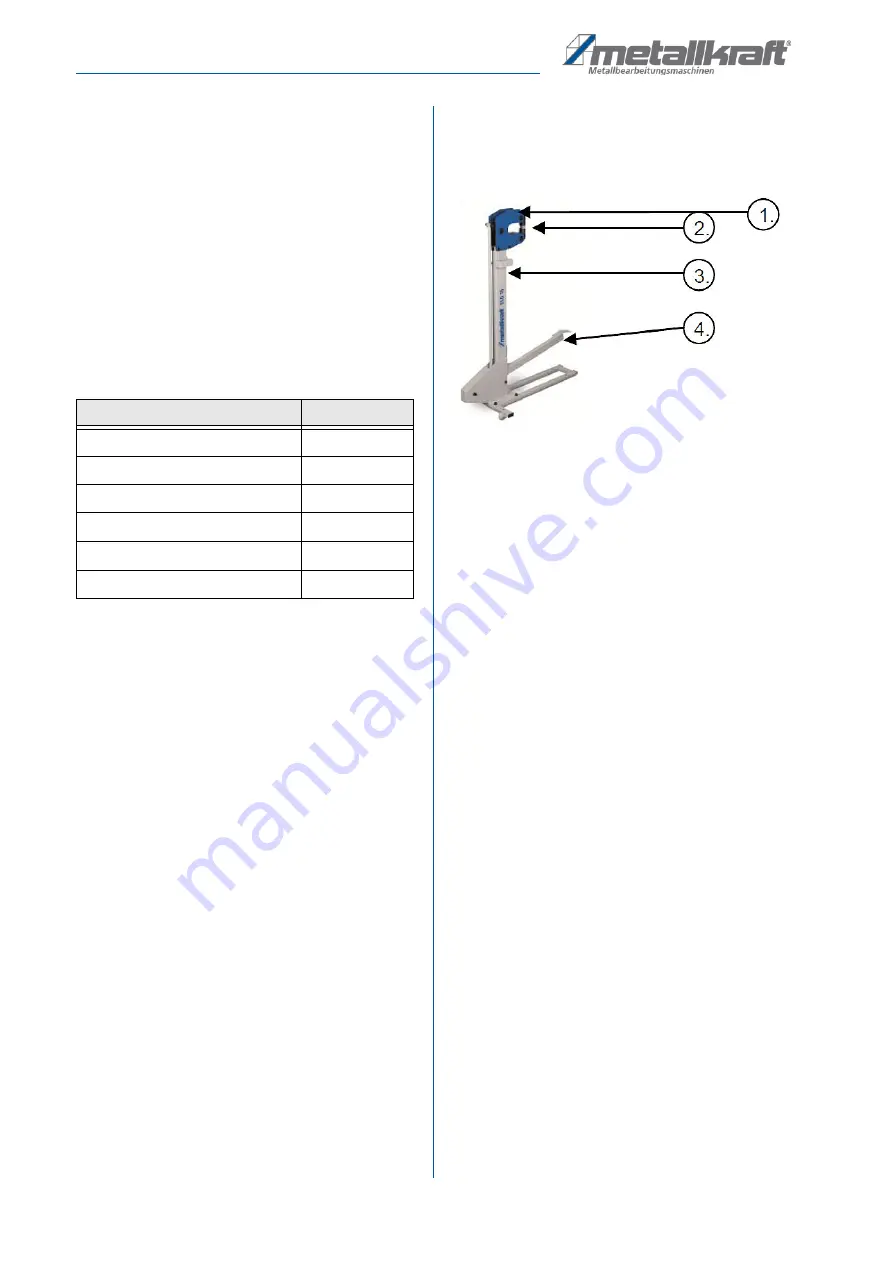

6.1 Illustrations

Fig. 1: Description of the device

1 - Cover for shrub and stretch jaw

2 - Upsetting and stretching jaws

3 - Main unit or pedestal

4 - Foot pedal

6.2 Scope of delivery

- Basic machine

- Stretching jaws

- Compression jaws

6.3 Accessories

- Compression jaw SET for SSG 16 for metal

Item number: 3776106

- Stretching jaw SET for SSG 16 for metal

Item number: 3776107

- Compression jaw SET for SSG 16 for aluminium

Item number: 3776108

- Stretching jaw SET for SSG 16 for aluminium

Item number: 3776109

Type

SSG 16

Max. sheet thickness

1,5 mm

Throat

153 mm

Length

1175 mm

Width / Depth

410 mm

Height

920 mm

Weight

36 kg