Operation

RBM 1305-15 E | Version 1.02

13

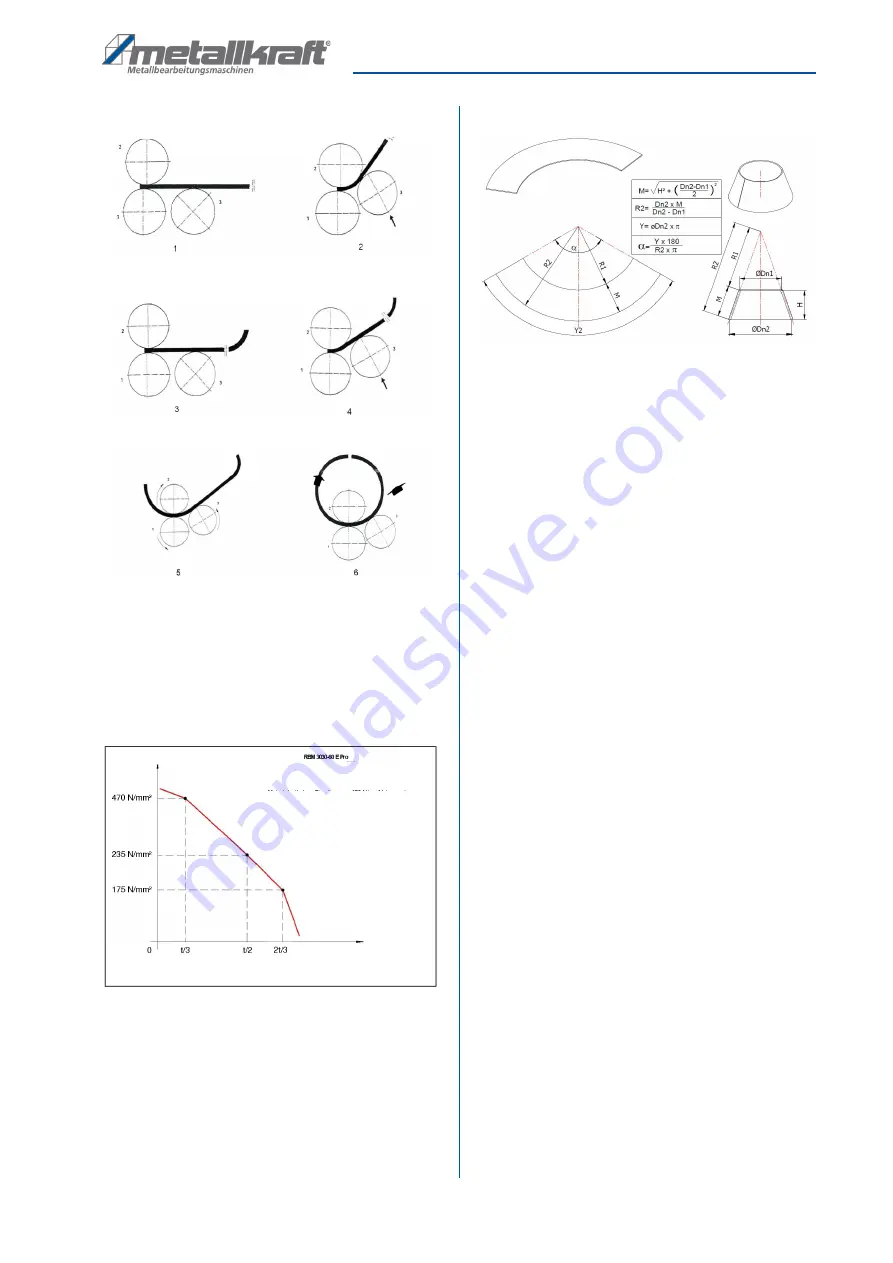

Fig. 11: Bending process

Conical bending

Conical bending is more difficult than normal bending.

The machine performance is reduced by 30% to 50%,

the conical bending capacity decreases by about 25%.

The material thickness must be reduced accordingly.

Fig. 12: Bending capacity chart

Calculation of the dimension of the workpiece

Fig. 13: Calculation of the dimension of the workpiece

Adjusting of the material thickness

Step 1: Loosen the knurled screw to the right of the ad-

justing screws.

Step 2:Turn the adjusting screws to raise or lower the

lower clamping roller.

Step 3:Insert the material between the rollers from the

front of the machine and set the rollers so that the

material is tight. Tighten the thumbscrews and

remove the material between the rollers.

Front adjusting screw and rear hand wheel

The 2 adjusting screws are installed in the left and right

side frames.

This allows the operator to raise or lower the pinch roller

so that the correct gap between the upper and lower

pinch rollers can be obtained to insert the desired mate-

rial into the machine.

The rear handwheel assist the operator in raising or low-

ering the guide roll, which determines the degree of

bending in the material being fed through the machine.

The hand wheel is equipped with a scale that helps the

operator to adjust.

Bending process

Step 1: After adjusting the diameter, insert the material

on the front of the roller and turn the control han-

dle clockwise until about half of the material has

passed through the rollers.

Step 2: When the roller is driven, make sure that the up-

per roller rotates counterclockwise. While the

material is being fed, lift the idler and continue

rotating until a semicircle is formed.

Top and bottom roll in

straight position

For finishing pre-banding

bring the rear roll upwards

Roll until the desired di-

ameter is achieved

Last pass

Yield strength

(material thickness)

Ratio of conical

bending capacity

t = bending capacity

The conical bending takes

place problem-free

material with a yield strength of 470 N/mm² until a diameter

660 mm with a thickness of 2 mm

material with a yield strength of 235 N/mm² until a diameter

660 mm with a thickness of 3 mm

material with a yield strength of 175 N/mm² until a diameter

660 mm with a thickness of 4 mm

Roll diameter: 220 mm

Pre bending capacity: 4 mm

Bending capacity: 6 mm

Example for

Conical bending in dependence of bending capacity

Notice: The values have been enlarged with the factor 3 in according of the roll diameter

For finishing pre-banding

bring the rear roll upwards

Turn sheet metal and posi-

tion it for the second pre-

bending