14

RBM 1305-15 E | Version 1.02

Cleaning, maintenance and service/repair

.

Step 3: After the formed semicircle, reinsert the un-

shaped material into the roller and turn the actua-

tion handle clockwise to form a complete circle.

Withdrawal of the workpiece

Step 1: After completing the bending process, support

the workpiece with a crane.

Step 2: Move the lower and rear roller down.

Step 3: Release the lock on the top roller.

Step 4: Swing top roller out.

Fig. 14: Swing out of the tp roller

Step 5: Remove workpiece. Use a crane to support the

workpiece.

Step 6: Swing the top roller back into the bearing and

lock it.

Fig. 15: Workpiece withdrawal with lifting device

9

Cleaning, maintenance and service/

repair

NOTE!

It is important that the roller rotates while you oper-

ate the cam lever. When the cam lever is engaged

while the rollers are not rotating, a noticeable flat

spot or line is formed across the width of the mate-

rial.

ATTENTION!

When the upper roller is tilted, the upper roller must

not be overloaded by the workpiece. The workpiece

must be supported by a crane.

Tips and recommendations

To ensure that the bending machine is always in

good operating condition, regular care and mainte-

nance work must be carried out.

DANGER!

Danger due to insufficient qualification of

persons!

Insufficiently qualified personnel can not assess the

risks involved in maintenance work on the machine

and expose themselves and others to the risk of seri-

ous injury.

- All maintenance work should only be carried out by

qualified persons.

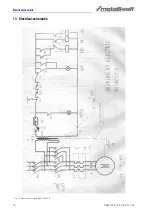

DANGER!

Danger to life due to electrical shock!

There is a danger to life when in contact with live

components.

- Always unplug the appliance before cleaning and

maintenance.

- Connections and repairs of the electrical equip-

ment may only be carried out by a qualified electri-

cian.

NOTE!

Before servicing and maintaining the bending

machine, the maintenance instructions must be read

carefully. Handling the Bending Machine is only per-

mitted to persons who are familiar with the Bending

Machine.

ATTENTION!

After servicing, maintenance and repair work, check

that all panels and guards are properly installed on

the machine again and that there is no more tools

inside or in the working area of the round bending

machine.

Damaged safety devices and parts must be repaired

or replaced by the customer service.