Safety

RBM 1305-15 E | Version 1.02

5

2.4 General safety regulations

Please note the following:

-Use the guards and secure them securely. Never work

without protections and get them working.

-Always keep the machine and its working environment

clean. Ensure adequate lighting.

-The bending machine may not be modified in its design

and may not be used for purposes other than those fore-

seen by the manufacturer.

-Never work under the influence of concentration-distur-

bing illnesses, fatigue, drugs, alcohol or medicines.

- Disconnect power before servicing. If any accessories

or maintenance are performed on the machine, the

power supply to the machine must be disconnected

before carrying out any work.

- Keep children and persons not familiar with the bend-

ing machine away from their work environment.

- Do not pull on the mains lead to pull the plug out of the

socket. Protect the cable from heat, oil and sharp

edges.

- Eliminate disturbances that affect safety immediately.

- Never leave the machine unattended.

- Keep the protective device in proper condition. The

machine must not be operated with removed protec-

tion devices.

- Secure the machine at the ON / OFF switch with a pad-

lock as soon as you leave the work area.

- Protect the round bending machine from moisture.

- Make sure that no parts are damaged before using the

Bending Machine. Damaged parts must be replaced

immediately to avoid danger sources.

- Do not overload the bending machine! You work better

and safer in the specified performance range. Use the

right tool! Make sure the tools are not dull or damaged.

- Only use original spare parts and accessories to avoid

possible risks and risks of accidents.

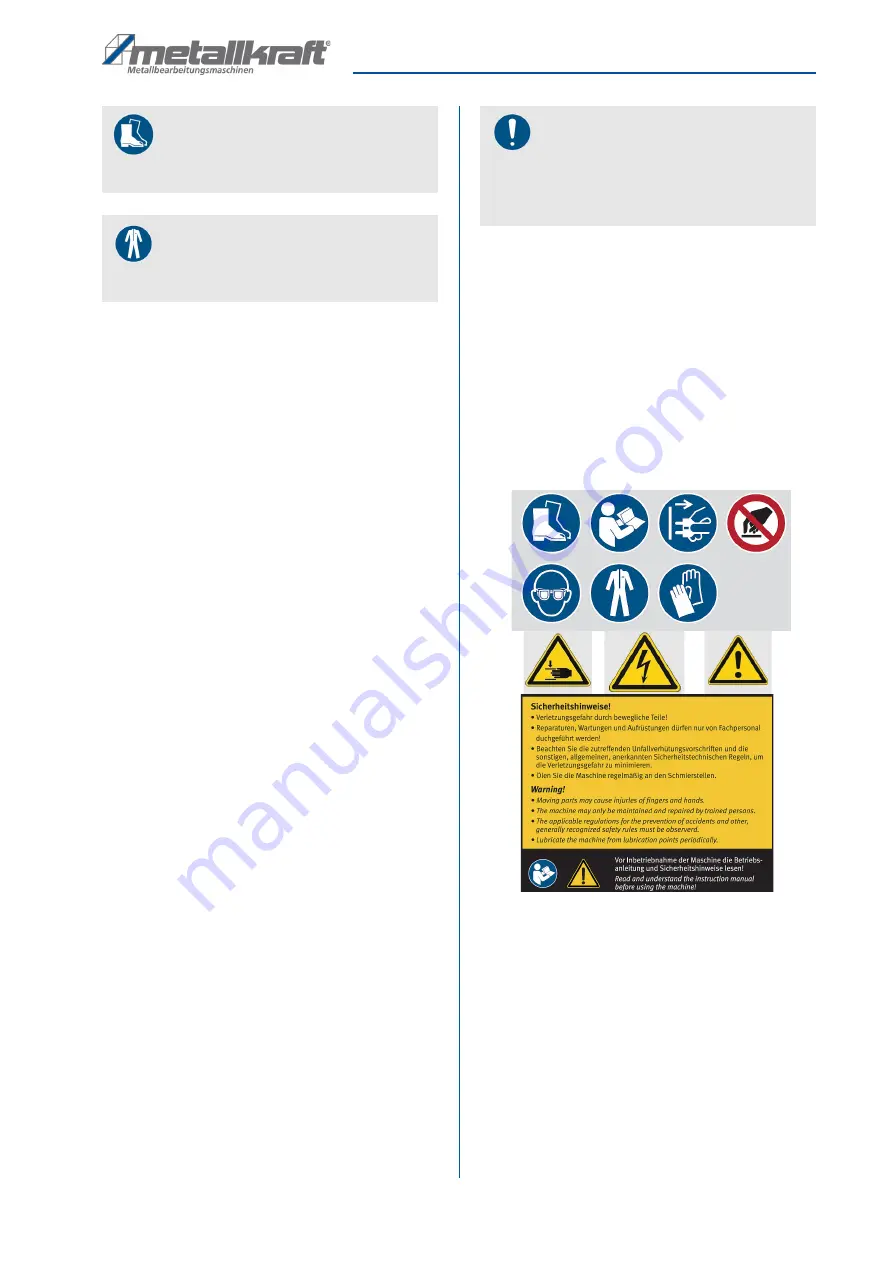

2.5 Safety lables on the machine

The machine has various warning labels and safety

markings that must be observed and followed. The

safety markings attached to the bending machine must

not be removed. Damaged or missing safety markings

can lead to malfunctions, personal injury and material

damage. They are to be replaced immediately.

If the safety markings are not immediately recognizable

and comprehensible, the round bending machine

should be taken out of operation until new safety mark-

ings have been made.

Fig. 1: Safety labels

Safety boots

Safety boots protect the feet from being crushed,

falling parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

NOTE!

This device should be grounded in accordance with

national electrical rules and local rules. This must be

done by a qualified electrician. The machine must be

earthed to protect the user from electric shock.