Setting up

AKM-Series 220 | Version 1.07

11

7 Setting up

7.1 Place of installation

In order to ensure good functioning of the notching ma-

chine and a long service life, the installation site should

meet the following criteria.

- The notching machine may only be installed and

operated in dry, frost-free, well-ventilated rooms.

- Avoid places near machines that cause chips or

dust.

- The place of installation must be vibration-free, i.e.

away from presses, planing machines, etc.

- The ground must be suitable for the work. Pay atten-

tion to the bearing capacity and evenness of the

ground.

- If necessary, protruding parts, such as support ta-

bles, etc., must be secured by on-site measures so

that persons are not endangered.

- Provide sufficient space for set-up and operating

personnel and material transport.

- Also consider accessibility for adjustment and

maintenance work.

- Provide adequate lighting (minimum value: 300 lux).

- The humidity should be in the range of 10% to 90%

and the measured room temperature should be bet-

ween max. 0°C - 50°C.

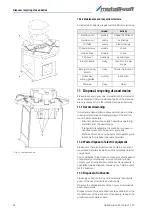

Setting up the machine:

Step 1: Make sure that the space around the machine is

sufficient for the application (Fig. 8). There must

be sufficient space for the operator and material

transport.

Step 2: Check each part of the machine for proper con-

dition before starting to set it up.

Step 3: Place the control foot pedal in the best position

for the application in front of the work area.

Fig. 8: Setup plan

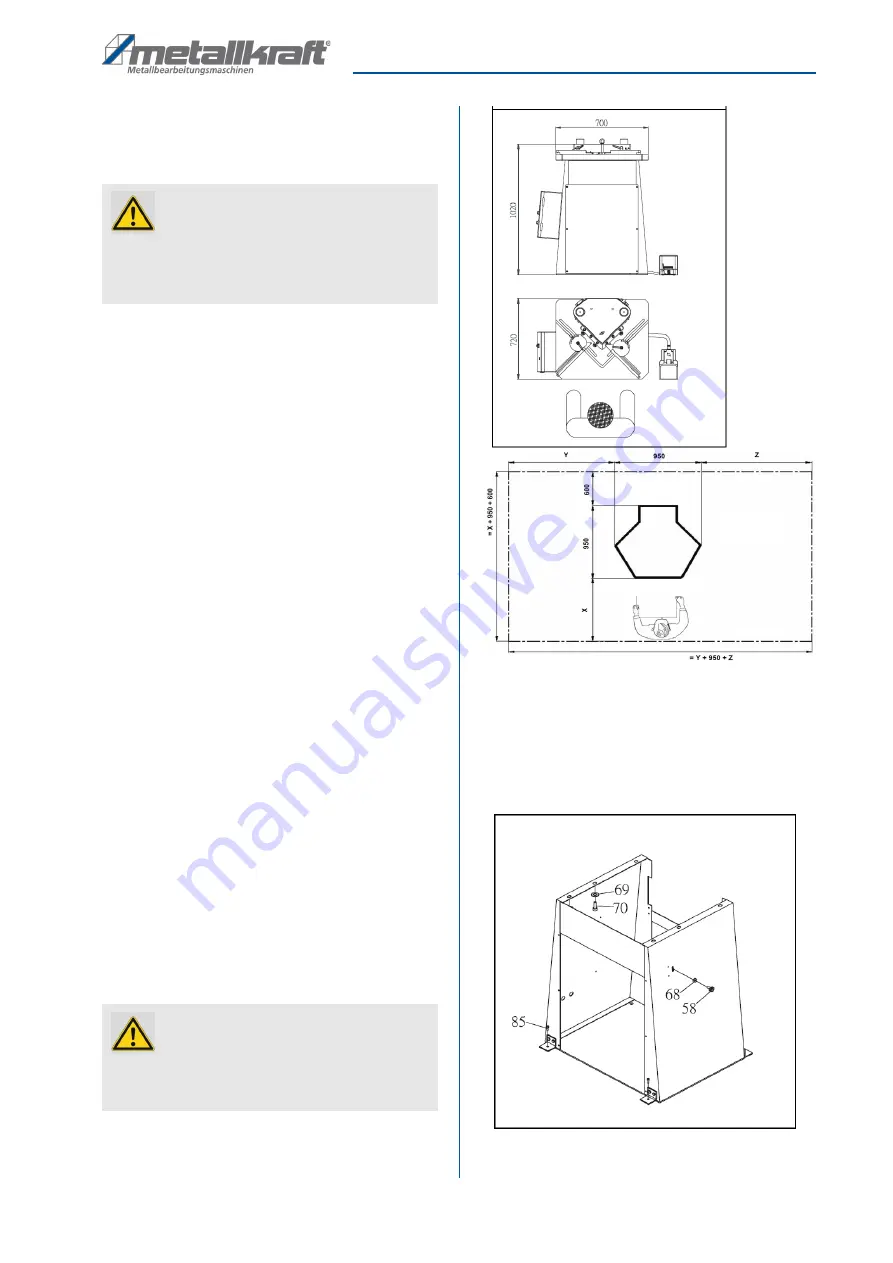

Step 4: Remove the hexagonal head cap screws 85

(Fig.9).

Step 5: Use a crane to lift the machine from the pallet

and move it to the working position (Fig.10).

Fig. 9: Removing the fixing screws

ATTENTION!

Check the load-bearing capacity of the ground

before you install the machine. The installation place

must be capatable of bearing the weight of the

machine and the workpieces.

ATTENTION!

The machine is delivered unfilled. Before commis-

sioning, hydraulic oil must be filled into the tank.

Only use suitable hydraulic oil for refilling.

Stock area of

cutted material

Free clearance

space

Stock area of material

which will be cut

Free space for operation and

material feed/removal

Required minimum width

R

equi

re

d

mi

nim

um

depth

Summary of Contents for 3834200

Page 32: ...www metallkraft de ...