14

AKM-Series 220 | Version 1.07

Settings

8 Settings

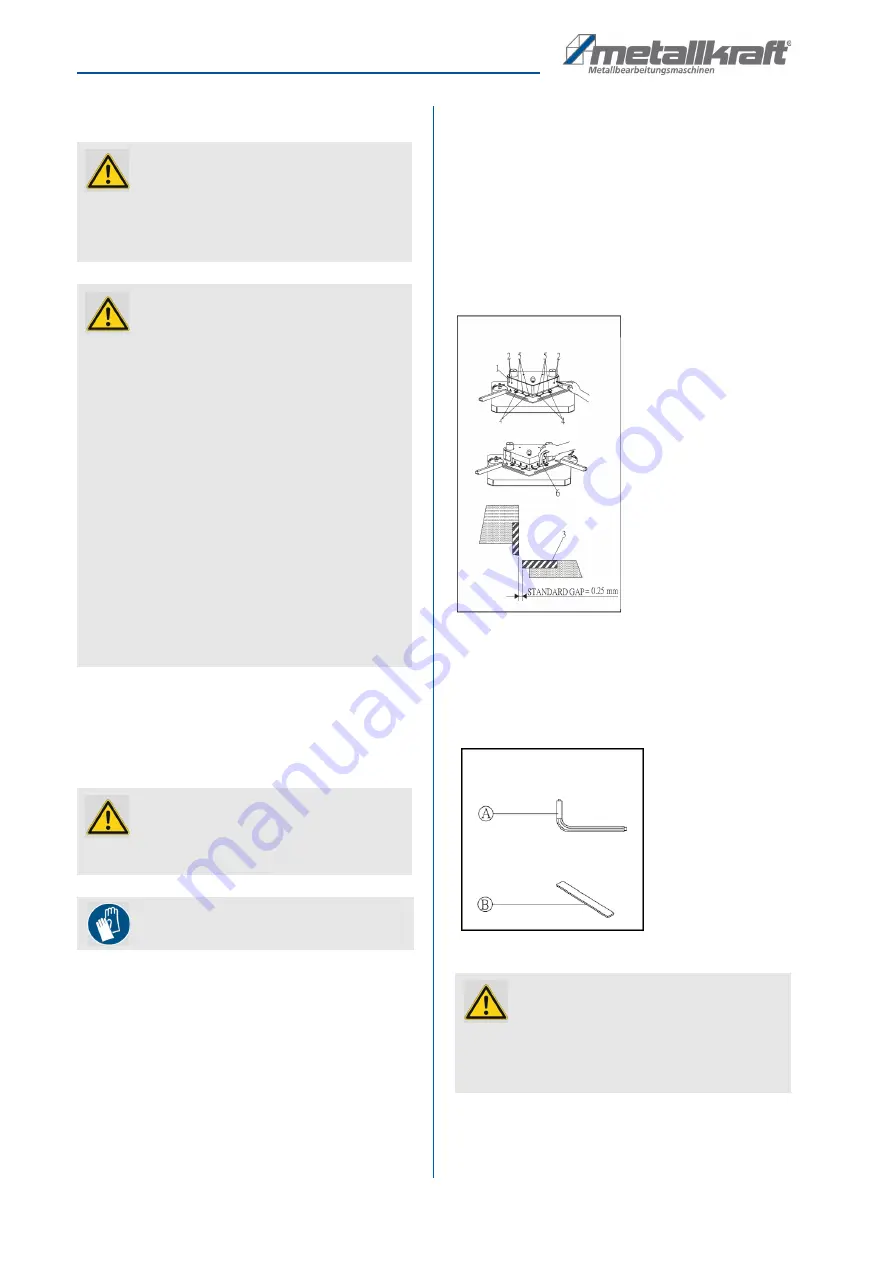

8.1 Setting the cutting gap tolerance

The cutting gap is adjusted after initial commissioning

and after each knife change.

- If the cutting gap is set too large, the notching

process may result in burr and chip formation. If the

cutting gap is set too small, the knives may be da-

maged and the stroke may block.

- Perform a few test cuts after adjusting the cutting

gap.

Step 1: Disconnect the power supply.

Step 2: Unscrew the screws (Pos. 2, Fig. 13) then re-

move the safety cover (Pos. 1, Fig. 13).

Step 3: Loose the bias screws (Pos. 4, Fig. 13) and

blade screws (Pos. 5, Fig. 13).

Step 4: Measure the tolerance by 0.25 mm thickness

gauge (Pos. 6, Fig. 13).

Step 5: Adjust the upper and lower blades against to the

thickness gauge. The thickness gauge should

be nower removed smoothly.

Step 6: Tight all the screws.

Fig. 13: Disassemble the safety cover

Tools for adjusting the cutting gap width (Fig. 14):

A

- Allen wrench for blade screw

B

- 0.25 mm thickness gauge.

Fig. 14: Tools for cutting gap adjustment

ATTENTION!

Settings on mechanically acting machine elements

may only be carried out on the machine by trained

specialists or specially trained and instructed per-

sons.

DANGER!

Incorrect mechanical settings can influence the

safety of the machine to such an extent that it cau-

ses a permanent danger. Careless behaviour can

put the personnel and the machine at risk when swit-

ching-on again.

- Before making any mechanical adjustments, al-

ways switch off the machine at the main switch and

secure the main switch against accidental restar-

ting, e.g. by attaching a warning sign.

- After carrying out the adjustment activities, make

sure that all covers and protective devices have

been properly mounted on the machine again.

- Do not leave any tools accidentally inserted during

setting activities. Before switching on the machine

again, make sure that all setting tools have actually

been removed. Make sure that no tools are left in-

side the machine, especially in the working area of

the machine mechanics.

ATTENTION!

There is a risk that the machine will be damaged if

the cutting gap is set incorrectly.

Use protective gloves!

ATTENTION!

No adjustment of the cutting gap is required for dif-

ferent sheet thicknesses. There are spring plates in

the system which automatically adjust the cutting

gap.

Summary of Contents for 3834200

Page 32: ...www metallkraft de ...