10

HKS 230 | Version 3.06

Settings and commissioning

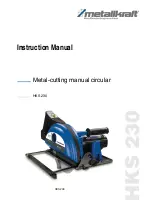

Fig. 6: Setting the bevel angle

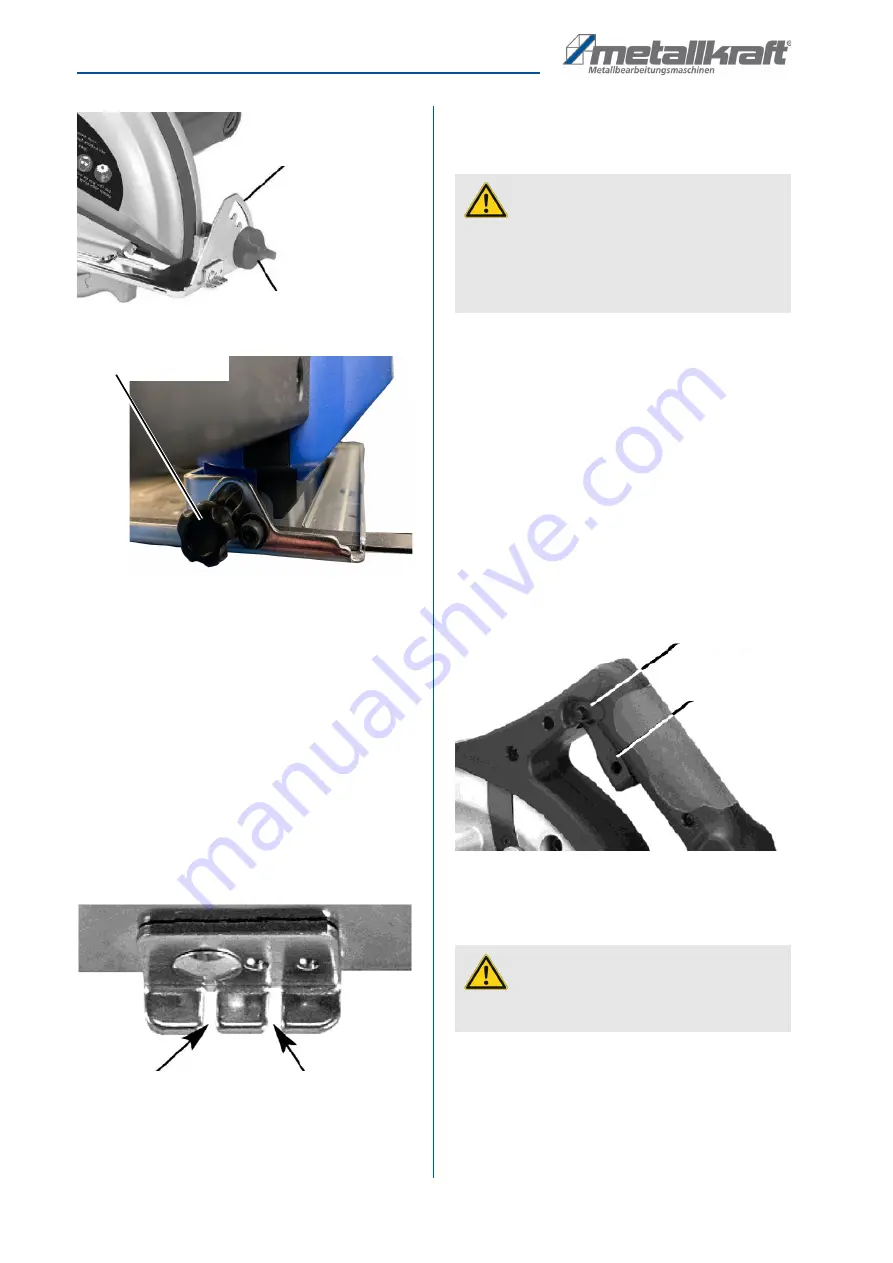

7.4 Using the cutting guide display

To support manually guided sawing, the cutting guide

display is located on the front end of the machine sup-

port.

During sawing, align the orientation slots with the cut

line.

Use the right orientation slot (between the two marks) for

straight cuts.

Use the left orientation slot for cuts below a bevel angle

of 45°.

Fig. 7: Cutting guide display

7.5 Switching the circular saw on and

off

Proceed as follows to switch on the manual circular saw:

Step 1: Connect the manual circular saw to the power

supply using the power plug.

Step 2: Press the button on the safety lock to release the

on/off switch.

Step 3: Press the on/off switch to start the machine.

Step 4: To switch off the manual circular saw, release

the on/off switch and allow to snap back to its

original position.

Fig. 8: On/off switch

7.6 Setting the rip fence

For cuts parallel to a straight workpiece edge, you will

achieve more precise straight ahead motion by using the

rip fence while guiding the cut than by guiding the work-

piece with your free hand.

Step 1: Insert the rip fence into the mounting straps pro-

vided on the machine support.

Clamping screw for bevel

angle (front)

Scale

Clamping screw for

bevel angle (rear)

Orientation groove

for 45 ° cuts

Orientation groove

for 90 ° cuts

ATTENTION!

Make sure that the connection voltage of the power

supply matches the value printed on the type plate.

Make sure that the on/off switch is on off position

before you connect the power plug to the power sup-

ply.

ATTENTION!

Before setting the rip fence disconnect the manual

circular saw from the power supply.

ON/OFF

Switch

Lock