Care, Maintenance and Repairs

HKS 230 | Version 3.06

13

8.1 Cleaning the machine

.

The metal-cutting circular saw should always be thor-

oughly cleaned after use.

Cleaning and maintenance table

Brush or wipe off all open machine parts with a brush or

cloth at regular intervals.

Treat bare metal work surfaces with anti-corrosive spray.

8.2 Changing the carbon brushes

The carbon brushes are subject to normal wear and

must be replaced when they reach their end-of-life.

The machine is equipped with a self-disconnecting brush

type. In other words, the motor will no longer run after

reaching the wear limit. For this reason, the carbon

brushes first need to be checked and possibly replaced if

the machine unexpectedly fails to start.

Proceed as follows:

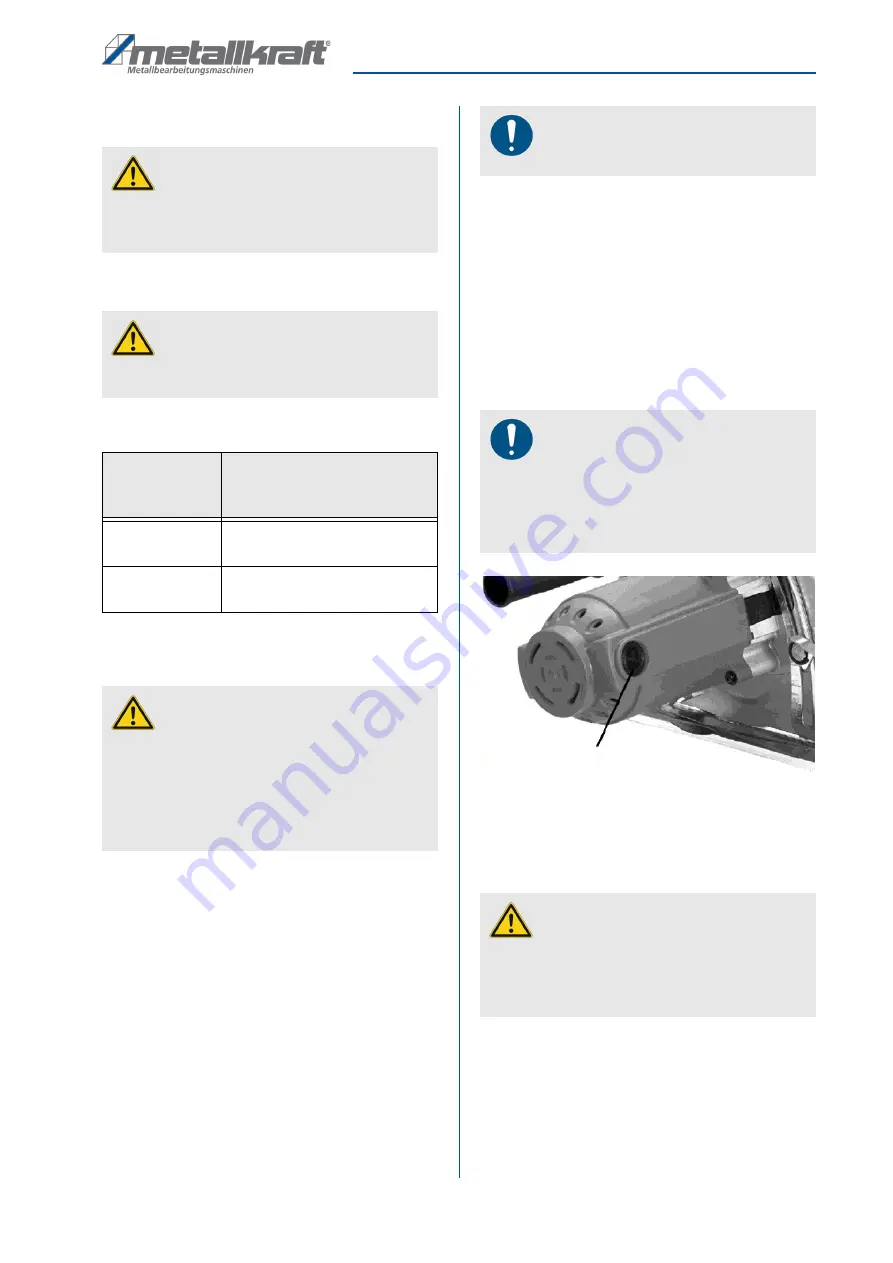

Step 1: Unscrew and remove the brush caps with a suit-

able screwdriver.

Step 2: Pull the carbon brushes out of the holder.

Step 3: Insert the brushes.

Step 4: Replace the brush caps and screw them back

down.

Fig. 11: Brush cap

8.3 Changing the power supply cable

ATTENTION!

- Never use solvents for cleaning plastic parts or

painted surfaces. This may cause the surface to

disintegrate and cause consequential damage.

ATTENTION!

All moving parts must be free of dirt and dust and

regularly greased or oiled (e.g., bolts).

Maintenance

interval in

operating hours

Maintenance point

Daily before use

Remove chips and clean the ma-

chine

Daily before use

Check the saw blade; replace if

needed.

ATTENTION!

- Never remove chips or grinding dust with your bare

hands. There is a risk of cuts through sharp edged

chips!

- Never remove chips or grinding dust with a com-

pressed air gun. This can lead to eye injuries and

damage machine components.

NOTE!

Always replace the carbon brushes as a pair.

NOTE!

If you only removed the carbon brushes for inspec-

tion, make sure that you reinsert them at the same

position and in the same order. Otherwise this will

cause reduced performance and increased brush

wear.

DANGER!

Risk of fatal injury through electric shock!

To reduce the risk due to electricity, work on the

power supply cable may only be performed by the

manufacturer or an authorised professional work-

shop.

Brush cap