Settings and commissioning

HKS 230 | Version 3.06

9

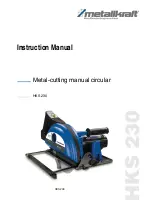

Step 4: Wearing protective gloves, remove the saw

blade and insert the new blade in its place on the

contact flange. Make sure that the teeth are

pointing forwards. In case of doubt, check the di-

rectional display printed on the saw blade.

Step 5: Position the outer saw blade flange with the flat

side facing the saw blade; then fit the fastening

screw and hand-tighten (Fig. 3).

Step 6: Use a hexagon socket wrench to turn the fasten-

ing screw clockwise. Press the saw blade lock

while doing so, and turn the saw blade support

with the wrench until you notice it engage.

Step 7: After the saw blade lock has engaged, tighten

the fastening screw to final torque by turning

clockwise.

Step 8: Before operating the saw, make sure that the

saw blade lock is back in its original position.

Fig. 4: Saw blade assembly

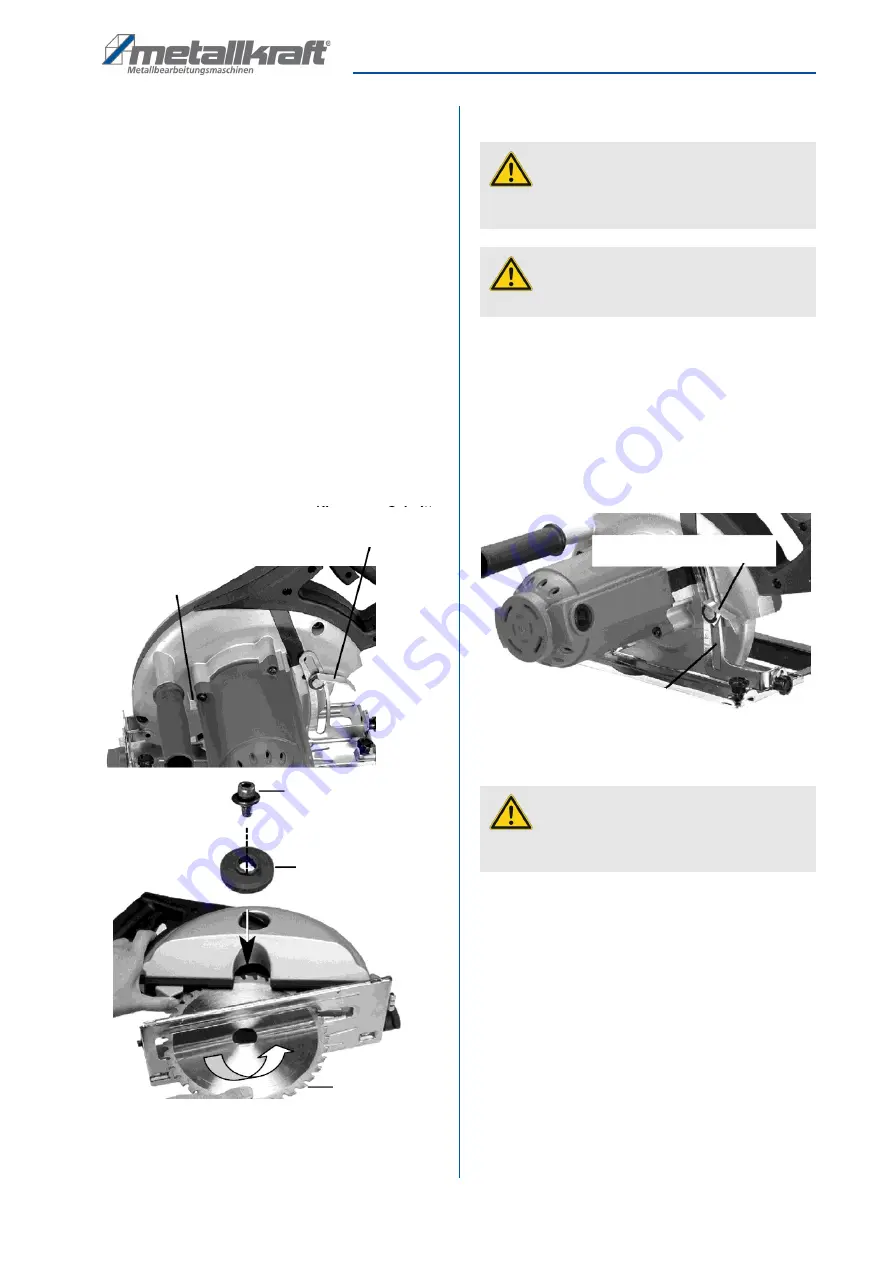

7.2 Setting the cutting depth

Adjust the cut so that the saw blade can penetrate the

entire depth of cut.

Step 1: Lift the cutting depth adjustment lever.

Step 2: Raise or lower the saw housing until you reach

the desired cutting depth. You can read off the

set value at the pointer on the integrated scale.

Step 3: Push the clamping lever fully down to ensure suf-

ficient clamping.

Fig. 5: Adjusting the cutting depth

7.3 Setting the bevel angle

When setting the bevel angle make sure that the saw

blade can penetrate through the entire material thick-

ness.

Step 1: Loosen the clamping screws for the bevel angle

at the front and rear (Fig. 6).

Step 2: Set the desired bevel angle.

Detents for bevel angles of

0°, 15°, 30° and 45°

are

provided on the front. If

other angles

are required,

clamp the clamping screw at the desired position

outside the detents.

Step 3: Firmly tighten the clamping screw on the back.

Saw blade

Screw

Flange

Sawblade

lock

Cutting depth adjust-

ment

WARNING!

Disconnect the machine from the power supply

before setting the cutting depth.

WARNING!

Never cut material thicker than 9 mm

WARNING!

Disconnect the machine from the power supply

before setting the bevel angle.

Clamping lever

Scale depth of cut