Settings and commissioning

HKS 320 | Version 1.04

11

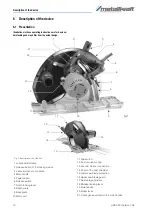

6.2 Scope of delivery

- Metal circular hand saw HKS 230

- Allen key

- Operating instructions

6.3 Accessories

- Guide rail 1400 mm

Item number: 3850030

- Saw blade for stainless steel Ø 320 x 2,2 x 25,4 mm Z84

Item number: 3853203

- Saw blade for steel Ø 320 x 2,2 x 25,4 mm Z80

Item number: 3853204

6.4 Saw blade selection

When sawing with a metal circular saw, make sure that

you choose the right saw blade or the correct tooth pitch

of the saw blade.

If the tooth pitch is too small and the cutting length too

long, the cut material cannot be absorbed by the

spaces between the teeth.

If the tooth pitch is too large, the saw tooth will start to

chop; this can cause teeth to break out.

7 Settings and commissioning

Causes of a setback and related warnings

A kickback is a sudden reaction to a jammed, jammed

or misaligned saw blade. It causes an uncontrolled lif-

ting of the saw out of the workpiece towards the opera-

tor.

If the saw blade is jammed or tied up by closing the kerf,

the saw blade stops and the motor reaction quickly

drives the unit back towards the operator.

If the saw blade is twisted or misaligned during cutting,

the teeth on the rear edge of the blade can dig into the

top of the wood, causing the blade to climb out of the

kerf and jump back towards the operator.

The kickback is a result of misuse of the saw or incorrect condi-

tions. This can be avoided by taking precautions.

a) Hold the saw with both hands and position your arms

so that they can withstand kickback forces. Position

your body on both sides of the saw blade, but not in

line with the blade. A kickback can cause the saw to

jump backwards. However, the kick-back forces can

be controlled by the operator if the appropriate

precautions are taken.

b) If the saw blade is jammed or if a cut is interrupted for

any reason, release the switch and hold the saw mo-

tionless in the material until the saw blade comes to a

complete stop.

c) Never attempt to remove the saw from the workpiece

or pull the saw backwards while the blade is moving.

Doing so may result in kickback.

d) When restarting a saw in the workpiece, centre the

saw blade in the kerf and check that the teeth do not

interfere with the material. If the saw blade is jam-

med, it may run up or kick back from the workpiece

when the saw is restarted.

e) Support large panels to minimise the risk of the blade

jamming and kickback. Large panels tend to sag un-

der their own weight. Supports must be placed on

both sides under the plate near the cut line and near

the edge of the plate.

f) Do not use blunt or damaged saw blades. Dull saw

blades create a narrow kerf that causes excessive

friction, blade jamming and kickback.

g) The locking levers for blade depth and bevel must be

set firmly and securely before cutting. If the saw

blade setting shifts during cutting, this can cause

jamming and kickback.

h) Be especially careful when blindly sawing into exi-

sting walls or other areas. The protruding blade may

cut objects that may cause kickback.

7.1 Function of the lower protective cover

a) Before each use, check that the lower guard is pro-

perly closed. Do not operate the saw if the lower guard

does not move freely and close immediately. Never

clamp or tie the lower guard in the open position. If the

saw is accidentally dropped, the bottom guard may

be bent. Lift the lower guard with the pull-back handle

and ensure that it moves freely and does not touch the

blade or other parts at any angle or depth of cut.

b) Check the function of the lower protection spring. If the

protection and the spring do not function properly, they

must be serviced before use. The lower protection may

be sluggish due to damaged parts, rubbery deposits

or accumulation of dirt.

DANGER!

Verwenden Sie nur Sägeblätter, deren maximal

zulässige Drehzahl der Maximaldrehzahl der Säge

entspricht oder darüber liegt.