12

HKS 320 | Version 1.04

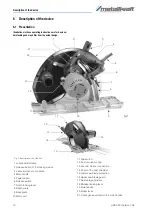

Settings and commissioning

c) The lower guard may only be retracted manually for

special cuts such as "plunge cuts" and "compound

cuts". Raise the lower guard by pulling back the

handle. As soon as the blade enters the material, the

lower guard must be released. For all other sawing

applications the lower guard should work automati-

cally.

d) Always make sure that the lower guard covers the

saw blade before placing the saw on the workbench

or floor. An unprotected rotating saw blade causes

the saw to run backwards and cut everything in its

path. Note that it takes a while for the saw blade to

stop after the switch is released.

7.2 Additional safety rules

- Tighten the saw blade holding screw and all

clamps before operation.

- Secure the workpiece properly. The workpiece

should be straight and firmly clamped to avoid

possible movement and jamming.

- Allow the saw blade to come to a complete stop

before removing or securing the workpiece or

changing the workpiece angle.

- Check the inner surfaces of the mandrel flanges

and the sides of the saw blade for foreign objects.

- Check the saw blade for cracks or other damage

before operation. Replace the cracked or dama-

ged saw blade immediately.

- Never start the tool with the workpiece against the

saw blade.

- Let the motor reach full speed before cutting.

- Important: When the cut is complete, release the

switch and wait until the rotating saw blade has

come to a complete stop before stopping the saw.

- Never operate the tool in an area with combustible

solids, liquids or gases. Sparks from the commuta-

tor / carbon brushes can cause a fire or explosion.

- There are certain applications for which this tool is

designed. The manufacturer strongly recom-

mends NOT to modify and/or use this tool for ap-

plications other than those for which it was desi-

gned. If you have any questions about the

application, DO NOT use the tool, but contact the

manufacturer.

- When cutting plastics, avoid melting the plastic by

using a saw blade specially designed for cutting

plastics.

- Do not overheat the tips of the saw blade. The use

of excessive force will not speed up the cutting

process. Let the tool determine the best feed

speed.

7.3 Electrical connection

The mains voltage must correspond to the voltage indi-

cated on the tool's nameplate.

Under no circumstances should the tool be used if the

power supply cable is damaged. A damaged cable

must be replaced immediately by an authorised service

agent. Do not attempt to repair the damaged cable

yourself. Using damaged power cords may result in

electric shock.

Extension cable

If an extension cable is required, it must have a suffi-

cient cross-section to avoid excessive voltage drop or

overheating. An excessive voltage drop will reduce the

power and may cause the motor to fail. Use only U.L.

and CSA listed extension cords. Never use two exten-

sion cords together. Use a long cable instead.

Saw blade

Only use saw blades with a diameter according to the

markings on the tool's nameplate: Only use saw blades

with a blade set (cutting width) of 1.8 mm to 3.6 mm and

a blade core thickness of at least 1.5 mm to a maximum

of 3.0 mm.the saw blades must be suitable for speeds

of up to 1700 rpm or faster. Do not use a grinding wheel

on this machine.

7.4 Installation of the saw blade

Wear breathing protection!

Wear hearing protection!

WARNING

Disconnect the machine from the electrical mains

before installing or removing the saw blade.

CAUTION

Only use saw blades that are permissible in terms of

dimensions and maximum speed. For your own

safety, only use original metal power saw blades.

CAUTION

Avoid injuries by touching the saw teeth.