Settings and commissioning

HKS 320 | Version 1.04

13

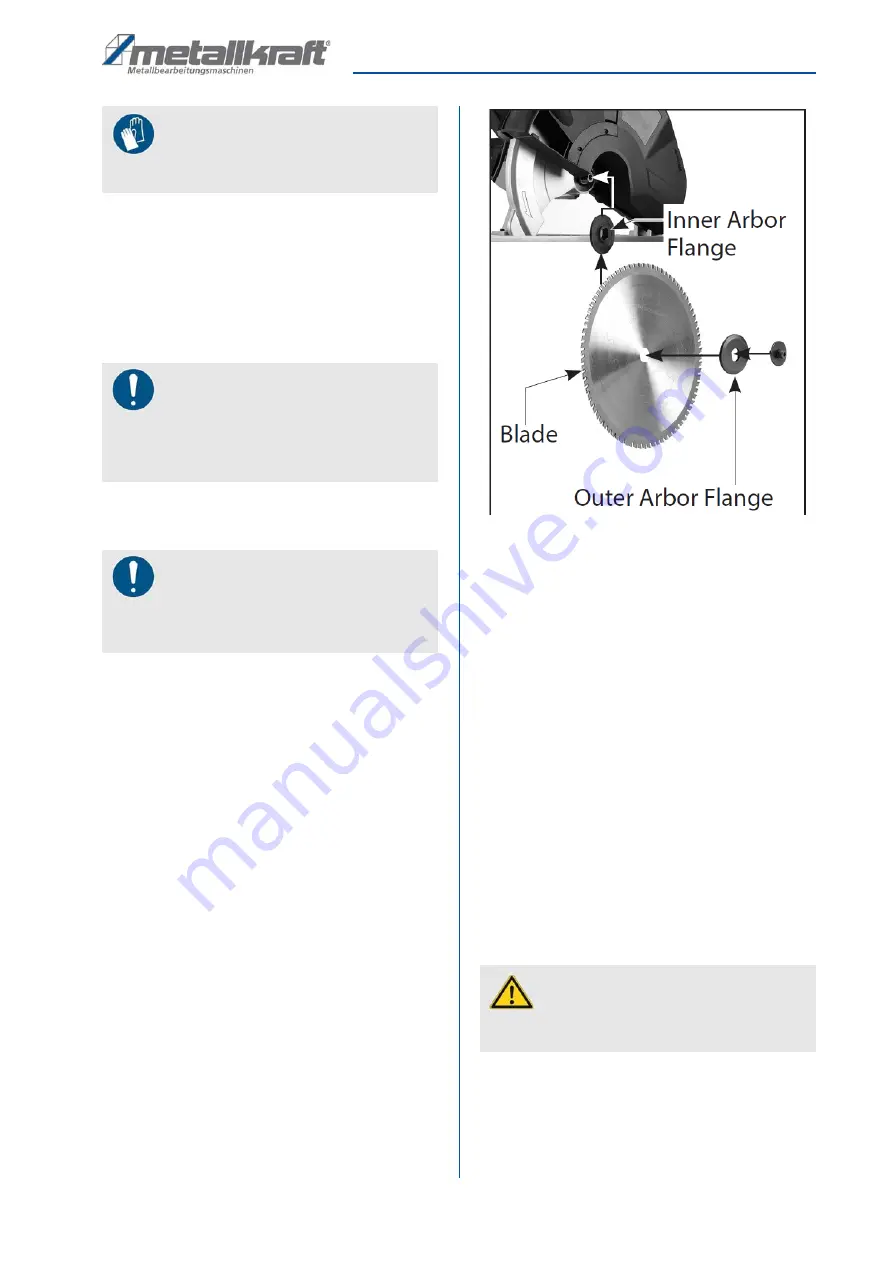

Step 1: Remove all accumulated residue in the guards

and around the assembly mandrel.

Step 2: Clean the inner flange of the mandrel (Fig.4)

Align the flange so that the correct side faces

the saw blade and place the new saw blade

on the shaft. Make sure that the teeth are poin-

ting forward.

Step 3: Place the outer mandrel flange on the mandrel

with the correct side towards the saw blade.

Step 4:Replace the saw blade holding screw and

tighten it hand-tight by turning it clockwise.

Step 5: Push the mandrel locking lever in and turn the

mandrel by hand until the lock engages the

mandrel. Tighten the saw blade holding

screw. Turn the arbor with the spanner to en-

sure that the arbor lock has loosened and re-

lease the arbor lock.

Fig. 4: Mounting the saw blade

7.5 Removing the saw blade

Removal is in the reverse order to the installation of the

saw blade. However, special care must be taken to en-

sure that no one is injured by the saw blade.

Step 1: Push the saw blade locking lever in and turn the

shaft with the spanner on the holding bolt until

the lock engages the shaft. Loosen the saw

blade holding bolt with the spanner supplied

and release the mandrel lock.

Step 2: Loosen the saw blade holding screw completely

and lift it and the outer flange away. Make sure

that the saw blade does not fall down.

Step 3: Carefully turn the lower blade guard out of the

way. The saw blade can now be removed.

7.6 Setting the cutting depth

Set the required cutting depth. A depth scale is availa-

ble.

Step 1: Release the depth adjustment locking lever.

Step 2: Set the value to the required depth.

Protective gloves

Wear protective gloves for all work connected with

the saw blade.

NOTE!

Use saw blades with a suitable arbor hole. The saw

blade must be designed for the maximum nominal

speed of the machine or higher. Avoid contact with

the blade teeth to prevent injury.

NOTE!

Make sure that the saw blade is centred (it is possi-

ble to tighten the saw blade at an angle between the

flanges).

WARNING

Disconnect the machine from the electrical mains

before adjusting the cutting depth.