Settings and commissioning

HKS 320 | Version 1.04

15

chamber is built into the upper saw blade guard. Clean

the dust chamber frequently to avoid overfilling.

Step 1: To clean the dust chamber, push the clip

upwards.

Step 2: Turn the dust chamber cover to the open posi-

tion and release the dust.

Step 3: When you are finished, put the cover back in the

closed position.

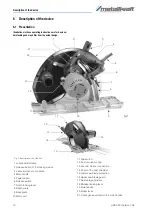

Fig. 9: Dust chamber

7.11 Switch the tool on and off

Step 1: Hold the device with both hands. Hold the de-

vice by the main handle and the side handle.

Switch on

Step 2: Press the button (Fig.10) to unlock.

Step 3: Press the release button (Fig.10).

Fig. 10: Trigger switch

Switch off

Step 1: Release the trigger switch.

Step 2: Wait until the saw blade stops rotating.

Step 3: Make sure that no body parts come into contact

with the saw blade while it is still rotating!

Step 4: Always have the lower saw blade guard closed

as soon as you remove the device from the

workpiece.

In this way the saw blade is again completely covered

by the outer protective cover.

7.12 Electronic overload protection

and load indicator light

This unit is equipped with a load indicator light that

shows the operator the load conditions, and whenever

the switch is turned on and the load conditions are nor-

mal, the indicator light is solid green (Fig. 11).

When the load approaches the overload conditions, the

indicator light will flash red.

If the operator continues to operate the machine under

overload conditions for an extended period of time, the

electronic overload protection unit will shut down the

machine.

The higher the overload, the faster the machine swit-

ches off.

In this case, always remove the machine from the work-

piece and let the machine run without load for a few mi-

nutes to allow the motor to cool down before continuing.

This prevents the motor from burning out.

Fig. 11: Load indicator light

WARNING

Make sure that the voltage of the circuit corresponds

to the voltage indicated on the machine's name-

plate and that the switch is set to "OFF" before

connecting the tool to the circuit.

Dust chamber

Clip

Dust port cap

Dust extractor port

Dust chamber cover

Lock release button

Trigger switch

Load indicator light