16

HKS 320 | Version 1.04

Settings and commissioning

7.13 Using the device

Effective control of this powerful saw requires two-hand

operation for maximum protection.

Do not use this tool continuously for 30 minutes. Pro-

perly support the workpiece and hold the saw BOTH

HANDS to avoid loss of control that could result in injury.

Always hold the side handle with your left hand and the

rear handle with your right hand to properly support the

saw by hand. Protect your eyes from injury with safety

glasses. Do not use cutting fluids or lubricants for the

saw blade.

Sawing

The unit must reach full speed before cutting starts and

should only be switched off after cutting is finished.

Operate the saw only away from you (push the circular

saw forward) and never in your direction (do not pull the

circular saw backward).

If you saw in your direction, there is a risk that the circu-

lar saw will accelerate out of the cutting groove (kick-

back) and cause serious injury.

The lower saw blade guard should open automatically

when it hits the edge of the workpiece. If it does not

open automatically, help it at the beginning of the cut by

pressing the kicker lever with the thumb of the left hand.

This will open the lower saw blade guard by about 20

degrees.

Saw cut:

Step 1: Make sure that the cutting depth is set as desi-

red.

Step 2: Place the front part of the sawing plate on the

workpiece.

Step 3: Switch on the machine.

Step 4: Push the device in cutting direction. Make sure

that the sawing plate remains firmly on the

workpiece.

Step 5: Switch off the device and let the lower blade

guard close completely after the cutting pro-

cess is finished.

Immersion cut

Step 1: Set the depth stop to the maximum cutting depth

and manually open the lower saw blade guard

until the saw blade touches the workpiece.

Step 2: When the device dips, the circular saw must be

held very securely, otherwise there is a risk of

kickback!

Step 3: Switch on the machine, let it reach full speed

and dip the saw into the workpiece.

Step 4: As soon as the saw is completely cut, push the

machine forward.

Step 5: When the cutting is complete, turn the machine

off and let it stop before removing it from the

workpiece.

7.14 Clamping the workpiece

Secure the workpiece properly. The workpiece should

be straight and firmly clamped to avoid possible move-

ment and jamming when the cut is almost complete.

Provide adequate support for long or wide workpieces.

Never position large or long workpieces so that they

bend in the middle or on the cutting surface, as this can

cause the saw blade to jam and bounce back. Instead,

support the workpiece with several wooden slats near

the cutting surface. Make sure that the saw blade has

come to a complete stop before removing, securing or

changing the workpiece angle.

Do not force the cut. Let the saw cut at the speed all-

owed by the type of cut and the workpiece.

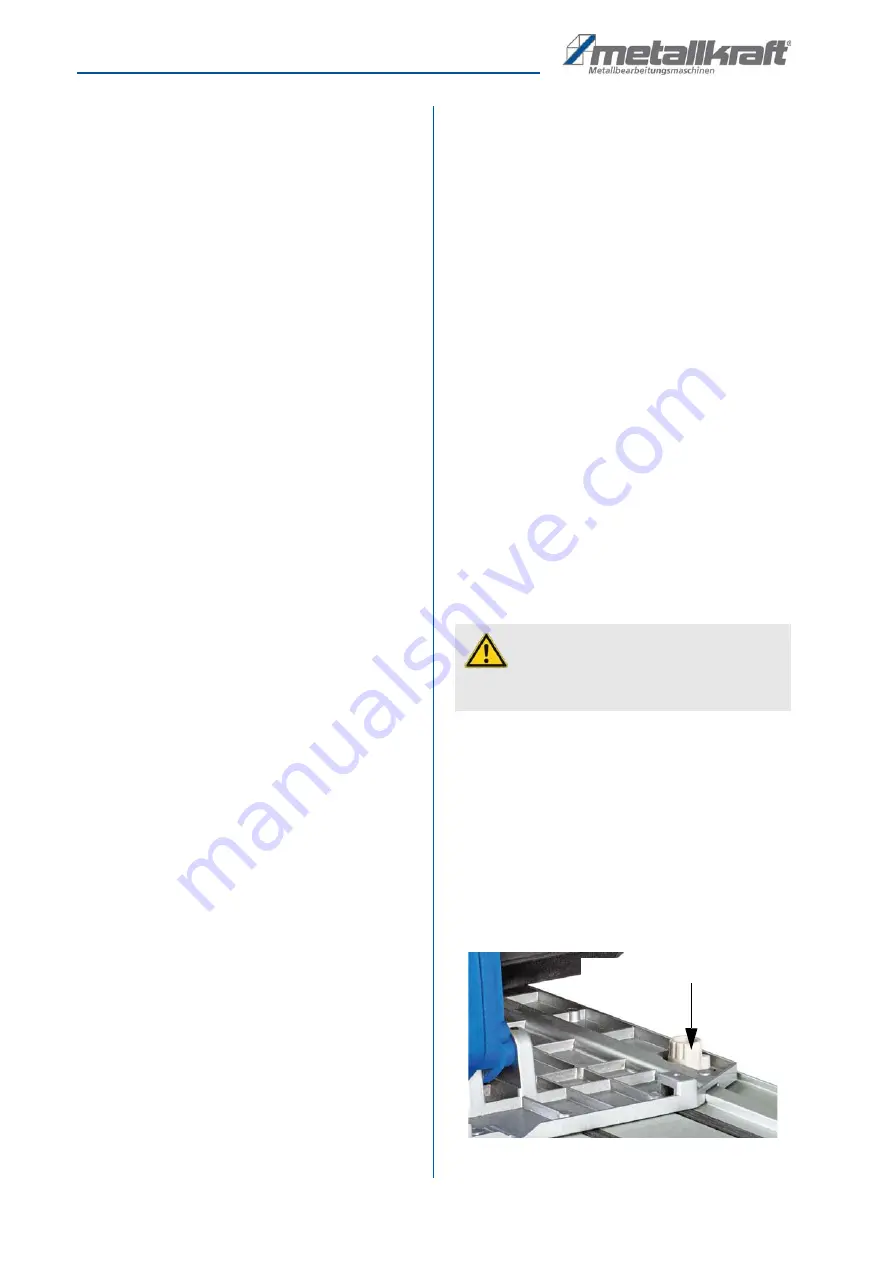

7.15 Guide rail

Guide rails (Fig.12) help to achieve precise straight cuts

and increase safety (This is an optional accessory). The

guide rail can be secured with C-clamps on request.

There are 2 guide play adjusters for optimum fit and sa-

fety. Adjust them evenly so that there is no looseness

and the base still slides freely.

Fig. 12: Guide rail

DANGER!

Keep the cable away from the cutting area so that it

does not get caught in the workpiece.

Guide clearance adjustor