Operation

GS 18 | Version 1.05

9

7

Operation

7.1 Preparation

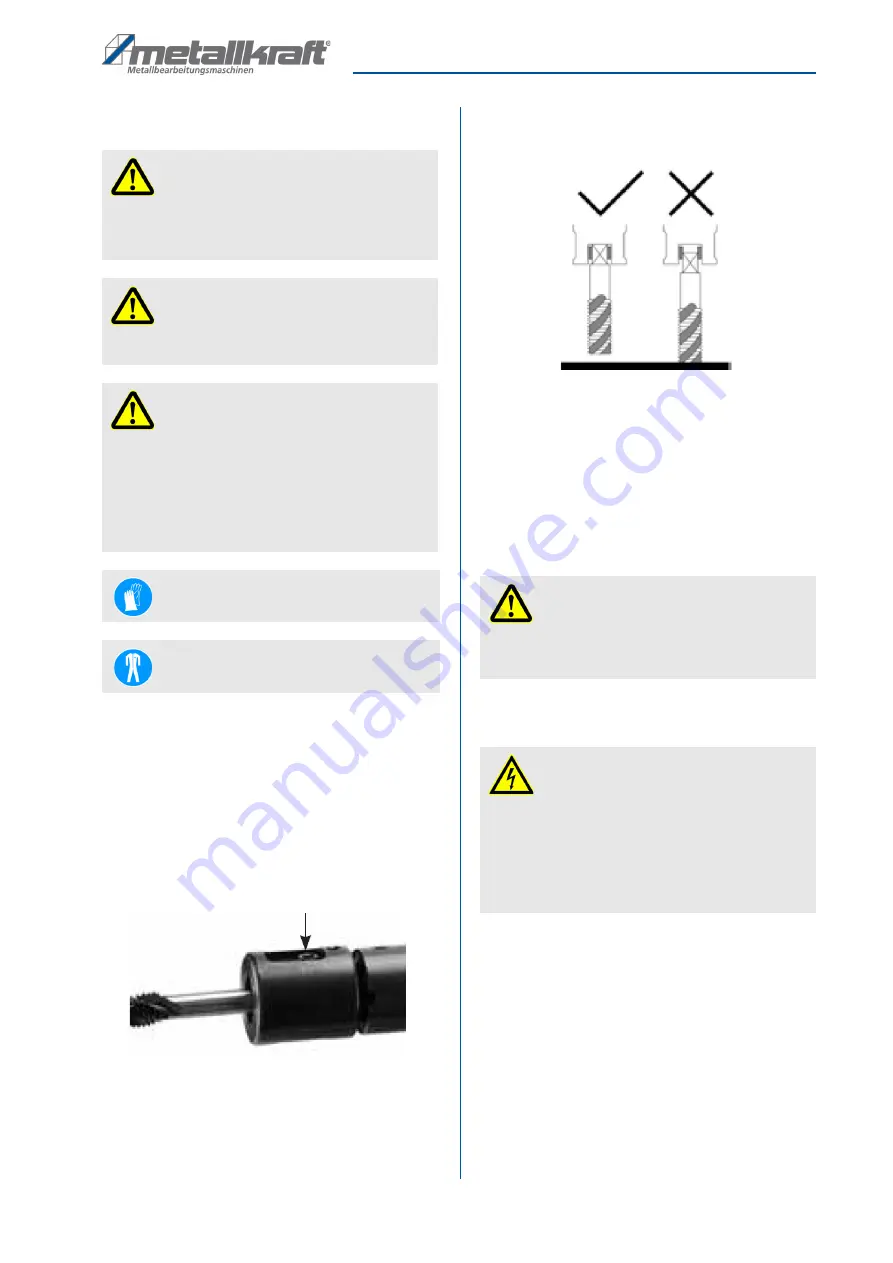

Step 1: Place the machine on a level surface to clamp

the desired Tapping Power Tool into the clamp-

ing device.

Step 2: Open the clamp device far enough to involve the

whole shaft of the tap.

Fig. 4: Holder for taps

Step 3: Insert the tap as far as possible into the clamp-

ing device.

Fig. 5: Inserting the tap

Step 4: Close the clamping device, making sure that the

shaft surfaces do not cant when closing and that

the shaft is inserted into the clamping device as

far as possible.

Step 5: Attach the side handle to your machine to guide

the machine safely with both hands during the

cutting process.

7.2 Electrical connection

When connecting the tap, make sure that:

- the power connection has the same characteris-

tics (voltage, mains frequency, phase angle) as

the motor.

- the mains voltage of 400 V is used.

Connect the Tapping Power Tool to the mains in the fol-

lowing steps:

Step 1: Check that the motor switch is off.

Step 2: Plug in the mains plug into the 230V socket after

clamping the tool.

ATTENTION!

- Make sure that the workpiece is not under pressure

before each cutting operation.

- Check that the workpiece is securely fastened.

ATTENTION!

Before connecting the machine to the mains, check

that the motor switch is off.

ATTENTION!

Never use the machine with larger taps than the

maximum permissible diameter. In relation to steel

14 mm and aluminum 16 mm in continuous opera-

tion. In occasional operation, the tap can be oper-

ated up to a diameter of 18mm. Readjust the slip

clutch if too much slippage occurs. For this please

contact the customer service under 1.2.

Wear protective gloves!

Wear protective clothing!

Locking screw for taps

ATTENTION!

Make sure that the shaft faces of the tap are inserted

as far as possible into the chuck and that the shaft

faces do not cant when the chuck is closed.

DANGER!

Danger to life due to electric current!

There is an immediate danger of electrocution on

contact with live components.

- The tapping power tool may only be connected by

electricians.

- Work on the electrical system should only be car-

ried out by qualified electricians.