6

GS-E Series | Version 1.09

Safety

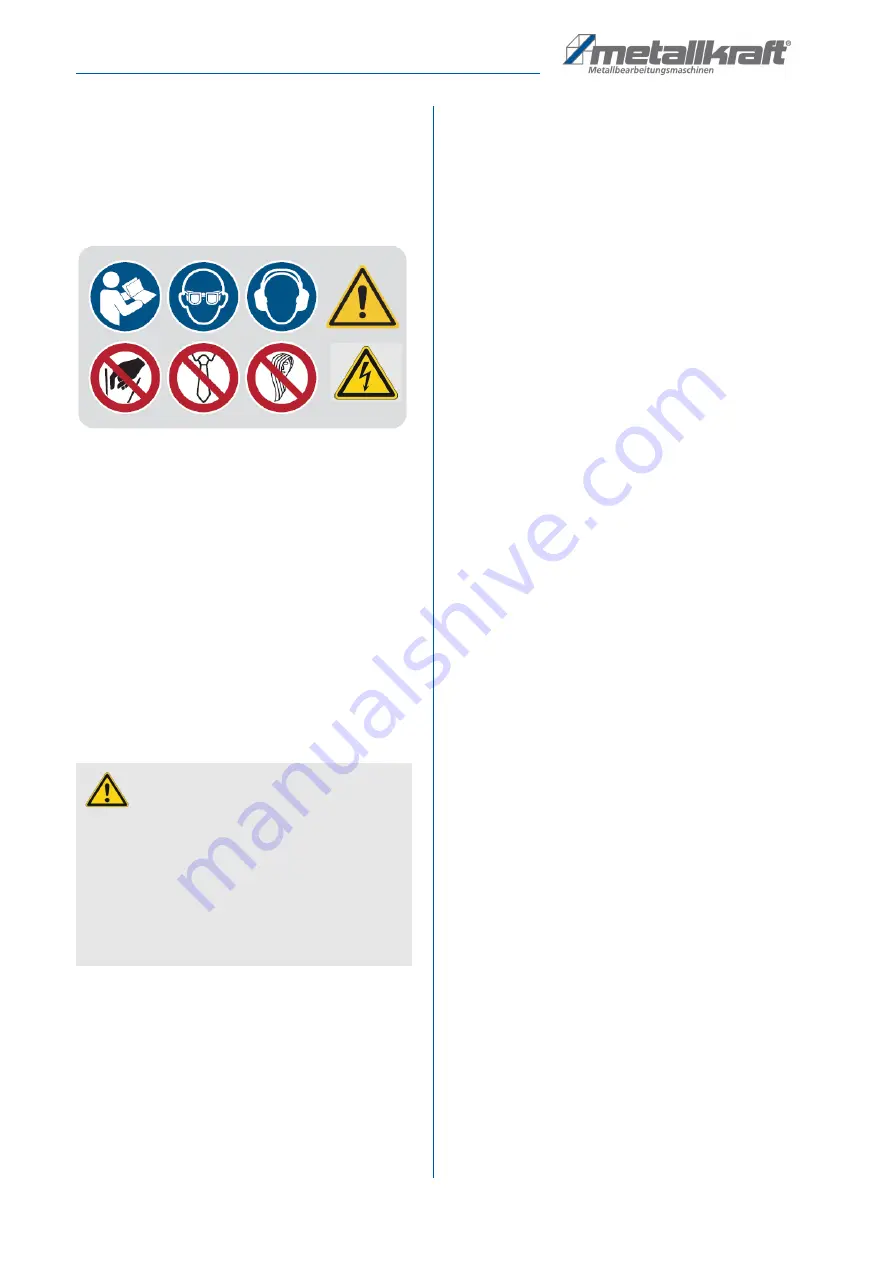

2.5 Safety labels on the thread tapping

machine

Various safety markings are attached to the thread tap-

ping machine (Fig. 1), which must be observed and follo-

wed:

Fig. 1: Safety labels - Mandatory symbols: Read instructions for use,

Wear eye protection, Wear ear protection I Warning symbols:

General warning sign | Electrical voltage I Prohibition symbols:

Do not reach in, Do not wear a tie, Do not wear open hair

The safety markings attached to the thread tapping ma-

chine must not be removed. Damaged or missing safety

markings can lead to incorrect actions, personal injury

and material damage. They must be replaced immedia-

tely.

If the safety markings are not recognizable and compre-

hensible at first glance, the thread tapping machine must

be taken out of operation until new safety markings have

been applied.

2.6 Safety devices

2.7 Safety data sheets

Safety data sheets for hazardous goods can be obtained

from your specialist dealer or by calling

+49 (0)951 / 96555-0.

Specialist dealers can find safety data sheets in the

download area of the partner portal.

2.8 Special safety rules for the thread

tapping machine

- Do not allow the machine to operate at overload,

especially outside of the tapping capacity.

- Check the wearing parts before using the machine.

Replace and repair them in good time.

- Lock the entire handle and secure the workpiece

firmly.

- Do not touch rotating parts when the electric tap-

ping machine is working.

- Keep children away from the threading machine.

- Keep people away from the work area when the

machine is working.

- Do not wear loose clothing or jewellery. They can

get caught in rotating parts. Non-slip footwear is re-

commended when operating the machine.

- Wear protective hair covering to hold back long

hair.

- Maintain the machine regularly. Keep the tap sharp

and add cutting oil while tapping.

- add cutting oil while tapping.

- Do not pile up the working material in the working

area of the machine.

- Always keep the working area clean.

- Do not use the electric tapping machine on flam-

mable, explosive, wet,

- undersized and unclean places.

- Do not work with blunt or damaged tools. This may

cause overstressing of the motor.

- Protect the motor. Make sure that no coolant, water

or other substances enter the motor.

- Metal chips are usually very sharp-edged and hot.

Never touch them with bare hands. Remove them

with a magnetic chip collector or a chip hook. Only

remove metal chips when the machine is switched

off.

WARNING!

Danger to life due to non-functio-

ning safety devices!

If safety devices do not function or are disabled,

there is a risk of serious injury or even death.

- Before starting work, check that all safety devices

are functional and correctly installed.

- Never override or bridge safety devices.

- Ensure that all safety devices are always acces-

sible.

Summary of Contents for 4450116

Page 22: ...www metallkraft de ...