Intended Use

GS-E Series | Version 1.09

7

3

Intended Use

The thread cutting machine is designed for the produc-

tion of threads for all materials made of metal or metal-

like materials in all material thicknesses. Only thread di-

ameters according to the specifications in the technical

data table may be cut.

Intended use also includes compliance with all the infor-

mation in these instructions.

3.1 Reasonably foreseeable misuse

Any use that goes beyond the intended use or is different

is deemed to be misuse.

Possible misuse can be:

- Use of the thread cutting machine for materials

other than metal (e.g. processing wood or plastic).

- The tapping machine must not be used for drilling

or screwing.

- Modifications to the machine or accessories.

- Maintenance work on an unsecured machine.

- Failure to observe the signs of wear and damage.

- Service work by untrained or unauthorized person-

nel.

- Use of accessories or spare parts that are not

approved by the manufacturer.

- Misuse of the machine.

- Operating the thread cutter if the operating instruc-

tions have not been read and understood in full.

- Deliberate or careless handling of the thread cut-

ting machine during operation.

- The use of an incompletely assembled machine.

Misuse of the thread cutting machine can lead to dange-

rous situations. Stürmer Maschinen GmbH assumes no

liability for constructive or technical changes to the

thread cutting machine. Claims of any kind due to da-

mage due to improper use are excluded.

3.2 Residual risks

Even if all safety instructions are observed and the ma-

chine is used according to the instructions, there are still

residual risks, which are listed below:

- Risk of injury to the upper limbs (e.g. hands, fin-

gers)

- Risk of injury from tripping over cables

- Hearing impairment when working for a long time

without hearing protection or when it is inadequate

- Electrical hazard from contact with parts and high

voltage (direct contact) or with parts that are under

high voltage due to a defect in the tap (indirect con-

tact)

- Heat development on components can lead to

burns and other injuries

- Danger from workpieces being thrown out

- Risk of injury to the eye from flying parts, even with

protective goggles

4

Technical Data

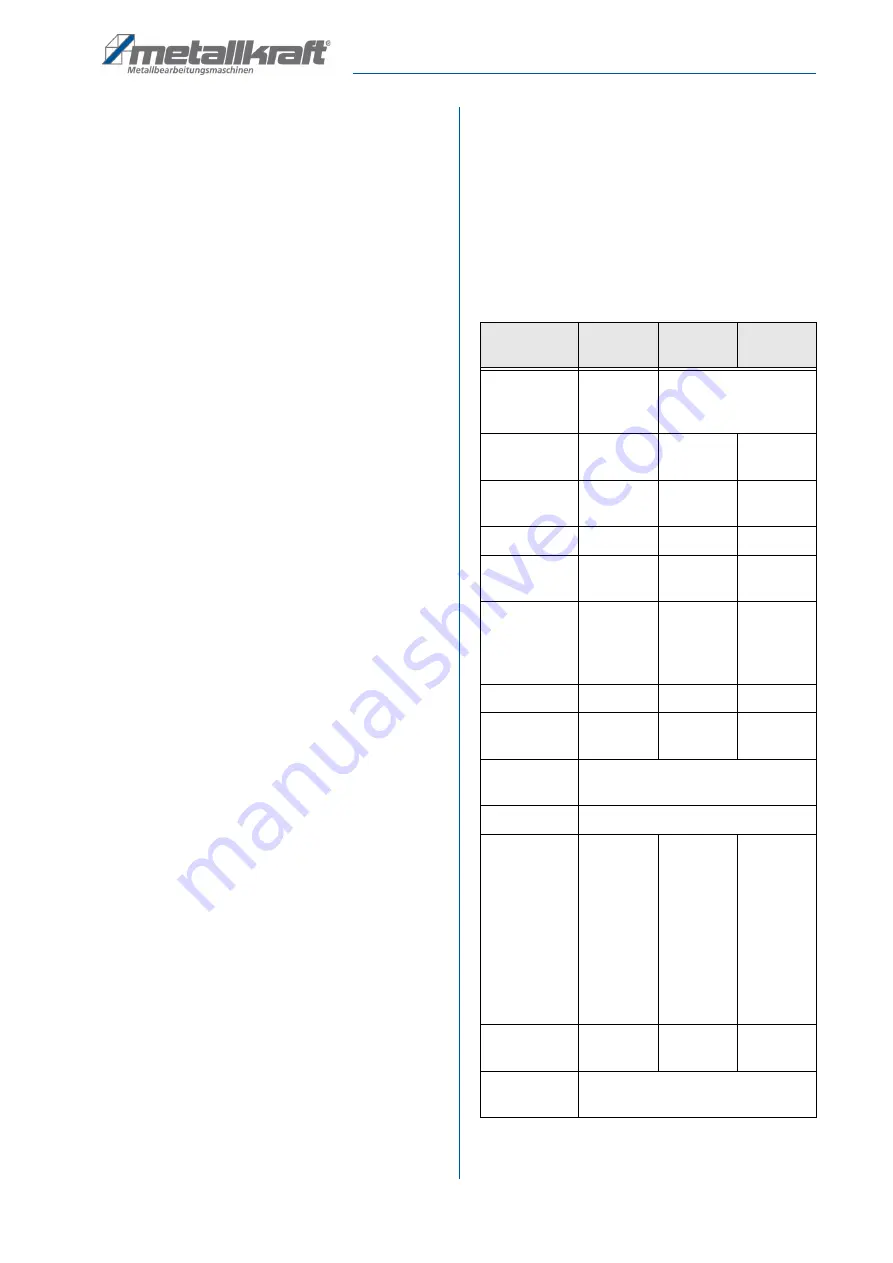

4.1 Table

Model GS

1100-16 E

1200-24

E

1200-36 E

Dimensions

(LxWxH)

approx.

930x60x

520 mm

1400x100x700 mm

Weight (Net)

approx.

25 kg

40 kg

42 kg

Supply

voltage

220 V /

50 Hz

220 V /

50 Hz

220 V /

50 Hz

Phase(s)

2 Ph

2 Ph

2 Ph

Stromart

AC/DC

4,5 A

7,3 A

7,3 A

Tapped

holes at

400 N/mm²

[M(x)-M(y)]

M3 - M16

M6 - M24

M6 - M36

Max. speed

312 min¯¹

200 min¯¹

156 min¯¹

Sound pres-

sure level Lp

59 dB(A)

73 dB(A)

73 dB(A)

Cutting

direction

universal direction

[vertical/horizontal]

Drive system

electrical

Quick

change

chuck [M]

M3-M6,

M8, M10,

M12,

M14, M16

M6, M8,

M10,M12,

M14,

M16,

M18,

M20,

M22-M24

M6, M8,

M10,M12,

M14,

M16,

M18,

M20,

M22-M24,

M27,

M30,

M33, M36

Cantilever

radius

1100 mm

1200 mm

1200 mm

Adjustable

angle

universal direction

Summary of Contents for 4450116

Page 22: ...www metallkraft de ...