8

GS-E Series | Version 1.09

Transport, packaging, storage

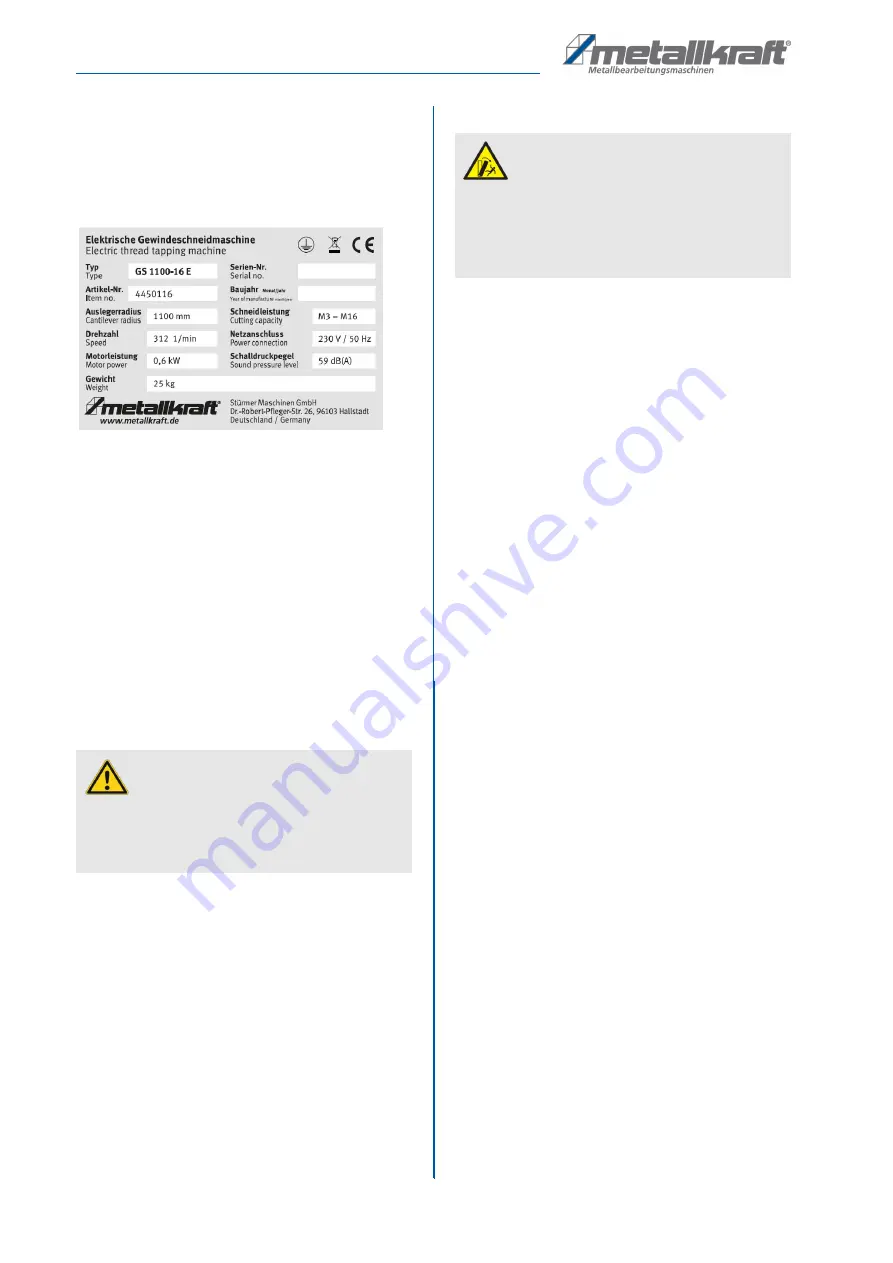

4.2 Type plate

The type plate with the following data for identification as

well as the CE marking is attached to the threading ma-

chine (Fig. 2).

Fig. 2: Type plate with CE marking of the thread cutting machine

GS 1100-16 E

5

Transport, packaging, storage

5.1 Delivery

The thread cutting machine must be checked for visible

transport damage and for completeness after delivery. If

the thread cutting machine shows damage or parts are

missing, this must be reported immediately to the trans-

port company or the dealer.

5.2 Transport

Improper transport of individual devices, unsecured de-

vices stacked on top of each other or next to each other

in packed or already unpacked condition is accident-

prone and can cause damage or malfunctions for which

we do not grant any liability or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently dimensioned industrial truck to

the installation site.

General risks during internal transport

Devices may only be transported by authorized and qua-

lified persons. Act responsibly during transport and al-

ways consider the consequences. Refrain from daring

and risky actions.

Gradients and descents (e.g. driveways, ramps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route for

possible danger points, unevenness and disturbances

as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points must

be inspected before transport. The removal of danger

spots, disturbances and unevenness at the time of trans-

port by other employees leads to considerable dangers.

Careful planning of internal transport is therefore essential.

5.3 Packaging

All packaging materials and packaging aids of the scrub-

bing vacuum cleaning machine are recyclable and must

always be recycled.

Shred cardboard packaging components and take them

to the waste paper collection.

The films are made of polyethylene (PE) and the padding

parts of polystyrene (PS). These materials should be ta-

ken to a collection point for recyclable materials or to

your local waste disposal company.

5.4 Storage

Store the tapping machine in a dry, clean, dust-free and

frost-free environment. It must not be stored in a room

with strongly oxidizing chemicals.

If the tapping machine must be stored in a damp room,

all bare metal parts must be greased against corrosion.

CAUTION!

Injuries caused by parts falling over or off a forklift,

pallet truck or transport vehicle.

Only use means of transport that can carry the total

weight and are suitable for it.

CAUTION: DANGER OF TIPPING!

The device may be lifted unsecured by a maximum

of 2cm.

Employees must be outside the danger zone, the

reach of loads. Warn employees and, if necessary,

advise employees of the hazard.

Summary of Contents for 4450116

Page 22: ...www metallkraft de ...