- 15

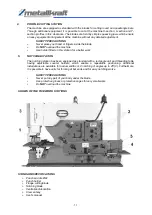

OPERATION OF THE MACHINE

Operation elements

All the electrical delivery of the machine passes through the main switch. In order to connect

this, rotate the switch clockwise. To confirm this, check that the control lamp starts lighten.

By pressing on the green “START” button, connect the motor (for the motor to be able to

function, the “STOP” button should be disconnected. This can be realized by rotating the red button

clockwise (or drawing this).

By pressing on the red “STOP” button, the motor will be stopped. The lightly pressed “STOP”

button gets locked at command. In order to loosen the button and to cause the machine to function

again, the “STOP” button will be turned clockwise ( or drawn ).

Note: The machine has two

pedals and double pistons. We

designed two workstations to work at

the same time; two operators can

make two operations at the same

time.

The pedal switch has three positions:

Over position

central position

lower position

If pedal is driven till the lower position and there remains fixed, the machine gets into the

deepest punching position. Nevertheless, the machine doesn’t turn back to the standby position until

the pedal is left loose.

The central pedal position allows the operator to effect unlimited positioning including over and

down course. This central position is very practical because it allows the operator to carry out touching

so that the work piece can be optimally positioned.

The switch “NORMAL / ADJUSTMENT” ensures that the machine is operated at touch

operation or performs production at normal functioning.

When the switch is arranged on “NORMAL”, the machine performs a normal and full work

cycle at each action of the foot pedal, that means the punch moves to the lowest position and then

gets again into the standby.

When the switch is arranged to “ADJUSTMENT” the

machine stops. When the pedal is left loose, the automatic

back course at this position has been cancelled.

REGULAR LUBRICATION INSTALLATION

The machine is equipped with a central lubrication

pump under pressure which is located at used, the system

should be adjusted to a pressure of 1-3 bars. When the

machine is at operation, a suitable pressure would be

maintained, through which the system will get back into the

previous filling pressure (approximately each 30 to 60

minutes).