- 20

ANGLE CUTTING INSTALLATION

This work station allows the cutting of big angles of 90

0

as well as cutting of the angles smaller

than 45

0

.

In order to cut angle profiles, the material is placed into the cutting zone through the fixing

installation and the support screw is adjusted to the corresponding material thickness.

Nevertheless, one should pay attention here in that longitudinal move of the profile still remains

possible.

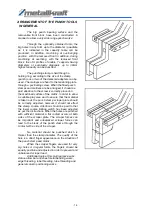

For the inclined cutting at 45

0

, the angles should be first cut on the length where the delivery for

the cutting of edges is also foreseen.

Please the first and in the blade, here the highest support position will be used.

Now cut about 6 mm from the end of the material, while you mountain 45

0

at vertical position.

Now place the other and in the blade, here the left support position is used and then cut the

material longitudinally. For this purpose, 45

0

should be maintained for from surface position of the

machine.

In order to obtain other cutting angles between 45

0

to 90

0

first cut the angle profile at length and

then cut the flange as per the required angle at the shearing station.

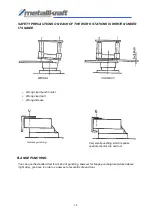

The cavity in the shear fixing installation allows that the angle profiles can be positioned for left or

right side cutting. Here, attention should be paid to that the fixing installation gets adjusted to the

related thickness.

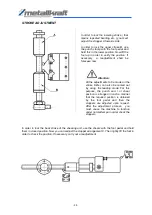

Each blade has four cutting edges and is held by the simple fixing screws. These blades should

not be sharpened. After four rotation these should be replaced by new blades.

WHILE ORDERING SPARE BLADES, ALWAYS STATE THE FOLLWING: MODEL, TYPE AND

MANUFACTURING NUMBER OF THE MACHINE