- 24

the lowering

ated bending

he stropper A

NOTCHING STATION

The threading station has quadrangles punch stamp as a standard equipment element and is

delivered with a threading table complete with adjustable lateral and rear counter holders, which

essentially simplify the repeatable positioning of the material.

The sharp notching tools can also be constructed at this work station. Optionally, the units for

narrower width of quadrangles or forms can also be delivered. Various units are also available for the

forming of bar ends.

A special feature of this work station is the possibility to fix some punch end units, that means

tools for smaller punching works up to a punch pressure of 40 t ( characteristics can be supplied upon

request ).

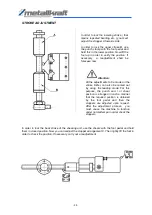

In case the grinding of the notching stamp is necessary, only grind the side and front surfaces

of the stamp. The matrixes have four cutting edges and should be turned in order to require

new cutting.

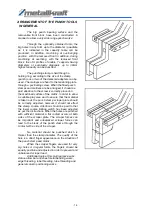

NOTCHING TOOLS – ADJUSTMENT

The below described steps should be followed for the change of the notching

(threading) blade set :

1.

Move the stamp to the exit position (that means fully open)

2.

Disconnect the machine at the main switch

3.

Remove the scraper finger and the stamp

4.

Remove the hole stamp and loosen the support

5.

Fix the new stamp

6.

Correct the machine and adjust it to “ADJUSTMENT” position. Fully lower the stamp and

disconnect the machine

7.

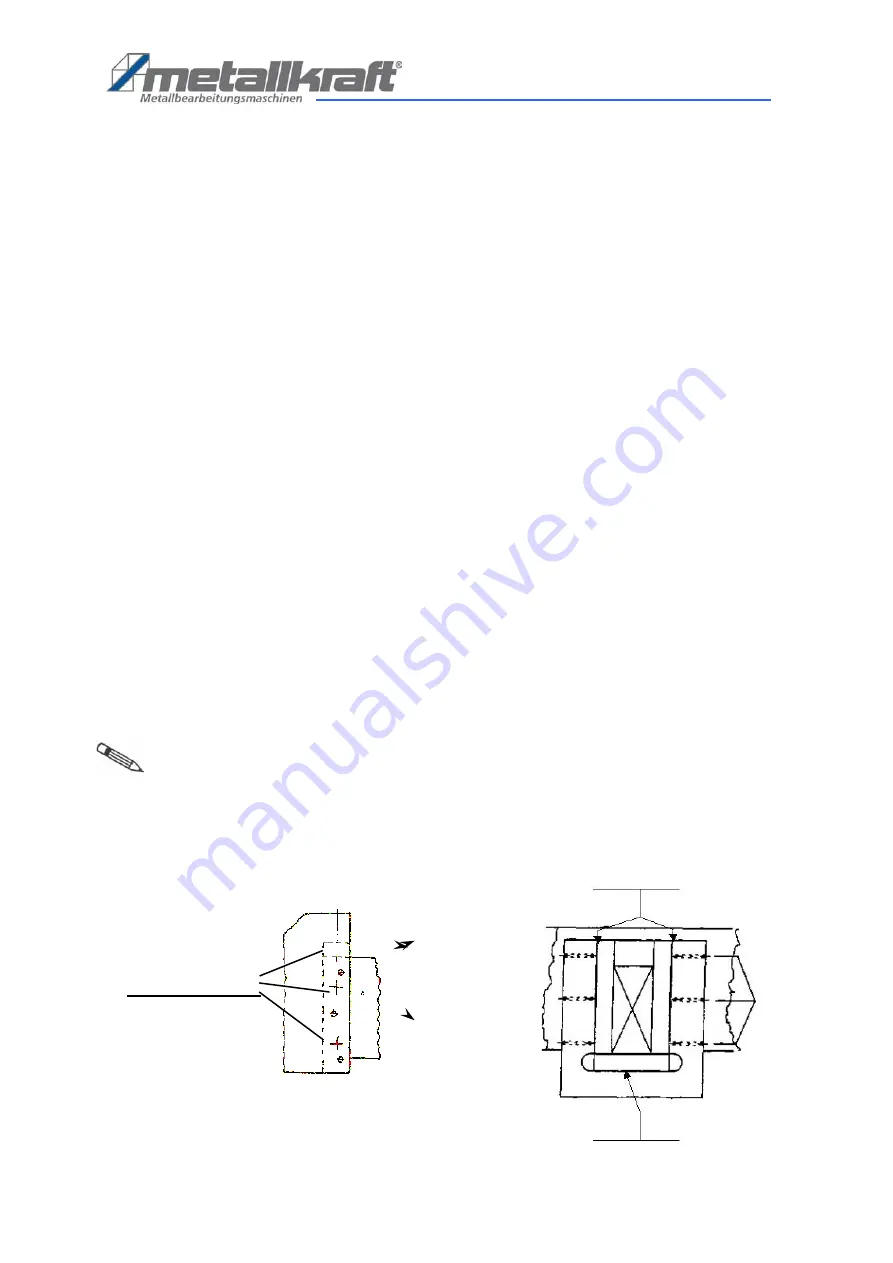

Take the hole ring into the support. Secure the front hole ring, then adjust the distance as

illustrated in the below sketch

8.

Secure the support on the machine after the adjustment of the front distance. Then adjust the side

distances as illustrated in the sketch

9.

Secure the side hole rings on the support. Check again the distances for safety

10. Connect to machine to loosen the stamp. Remount the scraper finger.

adjust the machine course in order to have motion as small as possible.

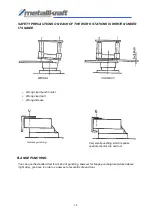

Note :

The lateral distances of the stamp should be adjusted as per the adjustments illustrated in the

sketch. Then the limiter will be arranged in such a manner that the lower edges of the hole ring will be

touched by the bas.

NOTCHING ADJUSTMENT

Lateral distance

0.1-0.2 mm

Adjustment screws

Front distance

0.1-0.2 mm