- 26

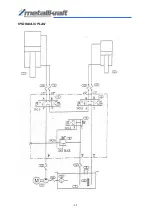

HYDRAULIC SYSTEM

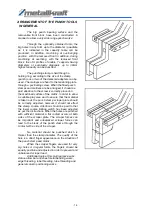

A 5.5 KW motor drives a hydraulic pump, which supplies the power cylinders on each end of

the machine through regulation valves. The punch cylinder is directly connected to the punching unit,

where the shear cylinder is connected through a turning lever.

Hydraulic oil

For this purpose are advised the oil types indicated in the machine plate. The oil filling and

ventilation supports are located in the tank where access is provided after removal of the protection

having cooling cavities located on machine base.

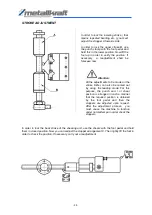

Absorption filter

The oil filter should be checked every twelve months. Access to the filter can be ensured after

having dismantled the screws of the tank protection. If necessary the filter can be washed in paraffin.

Impurity section

After having taken out the lower machine body protection, the section located under the main

chassis should be checked each year for dirt and impurities.

Cleaning

Under normal operation conditions, all the visible working parts should be regularly cleaned

from foreign substances that can prevent a standard use of the machine.

REGULAR MAINTENANCE

Daily Maintenance;

Before starting machine

Check full level in tank – top up us necessary

Check oil level in oil pump – top up us necessary

Check condition of all blades, punch and die

Check surrounding work area is tidy, remove and off-cuts, slugs from floor area

Clean off any mill scale which may have collected around the cutting apertures

Weekly maintenance;

But depending on work load

Examine power cable and food pedal cable for damage or chafing

Check movement of machine is smooth when running under no load condition

Monthly maintenance;

Check arm adjustment for any slackness

Yearly;

Change hydraulic fluid, check the oil absorption filter for any dirt and impurities