- 28

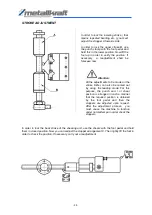

MACHINE ROD AND LEVER READJUSTMENT

After a preliminary working period (about 5 to 6 days), it will be necessary to carry out arran-gement

adjustments on the machine.

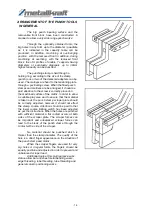

Punch rod

The arrangement of the rod will be realized with the help of a “rod leading plate”.

This plate should be readjusted.

The related adjustment screws are located at the exit side of the machine.

In order to adjust the rod, proceed in the following manner :

Remove the punch stamp

Loosen the safety nuts

Readjust the rod adjustment screw

(not to tighten too much)

Lock the screws with a safety nut

The adjustment control is to be made through a few in and out movement ( about 6 times ) of

the rod. Then the machine should be checked in adjustment mode. If the rod does not move here, the

plate should be readjusted and the process must be repeated.

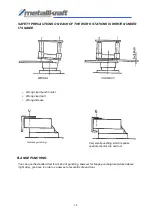

Shear lever

The machine should be disconnected before carrying out any readjustment works on the shear lever.

The readjustment of the pressure lines should be carried out from the delivery side of the machine.

For this purpose, proceed in the following manner:

Loosen the safety nuts ( M24 ) only of the three pressure line positions

Until alight pressure is obtained, rotate the adjustment screws clockwise

Tighten the safety nuts again and check the movement ability

Attention: The grooving stamp and matrixes are now not any more arranged. Please adjust

these again before the use of the machine.