6

KRBS 101 | Version 1.03

Intended use

Damaged or missing safety symbols at the machine may

lead to errors with personal and material damages. The

safety symbols which are applied on the machine must

not be removed. Damaged safety symbols must be re

-

placed immediately.

The machine must be put out of operation from the mo

-

ment when the labels are unable to be recognized and

understood at first glance, until new labels are attached.

3

Intended use

The pipe belt sander is designed exclusively for grinding

and deburring of various metallic, cold and non-combus

-

tible materials. It must not be operated in potentially ex

-

plosive environments.

For operation at the pipe grinding station on the front of

the device, the workpiece must be tightened with the ex

-

isting vise.

For operation on the belt grinding station on the back of

the device, the supplied support table must be mounted

before machining the workpiece.

When working on the various workstations, attention

must be paid to the respective direction of rotation of the

sanding belt (indicated by means of directional arrows at

the respective workstations). The direction of rotation

must be determined by means of a grinding test (eg

sparking of a test piece).

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or oth

-

erwise is considered misuse.

Misuse:

The Pipe belt sander must neither be used for grinding

flammable materials (e. g. magnesium, wood or similar).

The company Stürmer Maschinen GmbH is not liable for

any design and technical modifications on the the Ma

-

chine.

Any claims due to damages because of intended use are

excluded.

4

Technical Data

4.1 Table

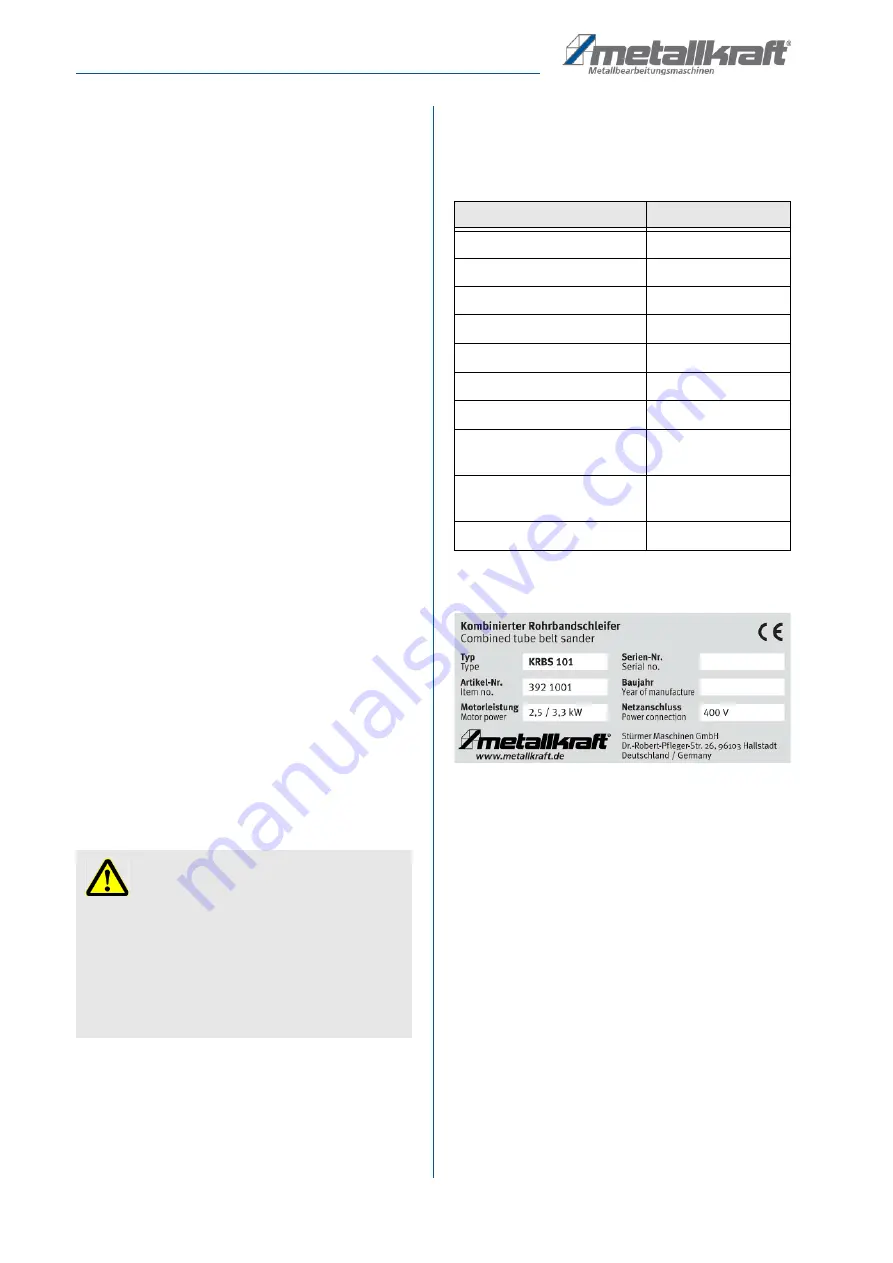

4.2 Type Plate

Fig. 2: Type Plate KRBS 101

5

Transport, packaging, storage

5.1 Delivery and transport

Delivery

Check if there are any visible transportation damages af

-

ter delivery of the Machine. If the Machine shows any

damages, immediately inform the carrier or the distribu

-

tor.

WARNING!

Danger in case of misuse!

A misuse of the Machine can result in dangerous sit

-

uations.

- Only operate the Machine in the power range given

in the technical specifications.

- Never bypass or override the safety devices.

- Only operate the Machine in a technically flawless

status.

Technical Data

Model KRBS 101

Belt dimensions

100 x 2000 mm

Motor output

2.5 kW/3.3 kW

Electrical connection

400 V/50 Hz

Motor speed

1400/2800 rpm

Belt speed

15–30 m/s

Grindable diameter

20 - 76 mm

Adjustable grinding angle

30 - 90° (0° - 60°)

Extraction duct nominal

width outside

2 x 74 mm

Dimensions L x W x H

1250 x 750 x 1140

mm

Weight

159 kg

Summary of Contents for KRBS 101

Page 1: ...KRBS 101 Instruction Manual KRBS 101 KRBS 101 Combined pipe section and belt grinding machine...

Page 20: ...20 KRBS 101 Version 1 03 Spare parts Fig 24 Spare Parts Drawing 2 KRBS 101...

Page 21: ...Spare parts KRBS 101 Version 1 03 21 Fig 25 Spare Parts Drawing 3 KRBS 101...

Page 22: ...22 KRBS 101 Version 1 03 Spare parts Fig 26 Spare Parts Drawing 4 KRBS 101...

Page 23: ...Wiring Diagram KRBS 101 Version 1 03 23 13 Wiring Diagram Fig 27 Wiring Diagram KRBS 101...

Page 25: ...Notes KRBS 101 Version 1 03 25 15 Notes...

Page 26: ...www metallkraft de...