8

KRBS 101 | Version 1.03

Installation

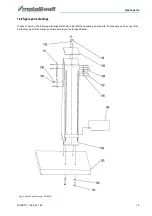

9 Drilling holes for anchoring

10 Clamping lever for height adjustment

11 Handwheel for adjusting the belt tension

12 Adjustment screw for height of the roller

13 Jaw

14 Clamping lever for clamping jaw

15 Guide cross slide

16 Feed lever

17 Clamping lever for cross slide

18 Grinding angle adjustment

19 Clamping prism

20 Cover tube grinding station

21 Transport lug

22 Adjustment screw

23 Contact rollers

24 START- and STOP Button

25 Workpiece stop

26 Internal hex

6.2 Scope of supply

- 1x Standard-grinding belt 36 grain

- 1x Spanner

- 2x Swarf catchment containers

- 1x Grinding roll Ø 42mm

6.3 Accessories

- Roller for 3/8“ pipe

- Roller for 1/2“ pipe

- Roller for 22 mm pipe

- Roller for 3/4“ pipe

- Roller for 28 mm pipe

- Roller for 1“ pipe

- Roller for 34 mm pipe

- Roller for 1 1/4“ pipe

- Roller for 44 mm pipe

- Roller for 1 1/2“ pipe

- Roller for 50 mm pipe

- Roller for 2“ pipe

- Roller for 62 mm pipe

- Roller for 2 1/2“ pipe

- Roller for 28 mm pipe

- Extraction unit (optional)

7

Installation

In order to attain good functionality as well as a long du

-

rability of the Machine the installation site should fulfil

certain criteria.

- The Machine may only be placed and operated in a

dry, venti lated space.

- Do not place the machine in the neighbourhood of

dust- and chips producing machines.

- The place of erection should be free of vibrations,

so away from presses, planers etc.

- The floor hast to be suitable for the work. Pay at

-

tention to bearing capacity and levelness of the

floor.

- Protruding parts, like f.i. stop plate grips etc. need

to be made safe in such away that people are not

jeopardized.

- there should be enough place for operation staff

and transport of material.

- Think also of the accessibility for adjustment and

maintenance work.

- Take care of sufficient light (minimal 300 Lux)

ATTENTION!

Check the floor loading capacity before you install

the machine. The place of installation must be capa

-

ble of bearing the weight of the machine and the

workpieces.

Summary of Contents for KRBS 101

Page 1: ...KRBS 101 Instruction Manual KRBS 101 KRBS 101 Combined pipe section and belt grinding machine...

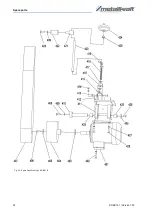

Page 20: ...20 KRBS 101 Version 1 03 Spare parts Fig 24 Spare Parts Drawing 2 KRBS 101...

Page 21: ...Spare parts KRBS 101 Version 1 03 21 Fig 25 Spare Parts Drawing 3 KRBS 101...

Page 22: ...22 KRBS 101 Version 1 03 Spare parts Fig 26 Spare Parts Drawing 4 KRBS 101...

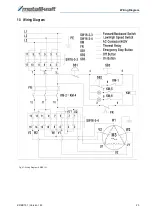

Page 23: ...Wiring Diagram KRBS 101 Version 1 03 23 13 Wiring Diagram Fig 27 Wiring Diagram KRBS 101...

Page 25: ...Notes KRBS 101 Version 1 03 25 15 Notes...

Page 26: ...www metallkraft de...