Commissioning

PRM FH | Version 1.04 | EN

17

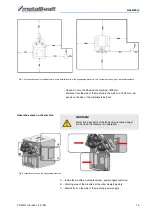

To convert the machine to the horizontal working position, proceed as follows:

Step 1: Wrap a belt with a load capacity of approx. 1 ton around the shaft of the

upper roller (PRM 50 FH - 1, Fig. 11) or hook it into the upper ring eye

with a load hook for transport (PRM 60 FH, Fig. 11, right).

Step 2: Lift the ring bending machine slowly using a forklift or crane.

Step 3: Slowly lower the ring bending machine and pull it with the belt or load

hook into the horizontal position.

Fig. 11: Convert the ring bending machine

Filling the ring bending machine

with the oil

The ring bending machine must be filled with oil after installation.

8

Commissioning

NOTE!

After installation, remove the protective agent from the rol-

lers, which has been applied in the factory to protect against

rusting.

- Use a cloth and usual solvents (e.g. benzine).

- Do not use water, nitro solvents, etc.!

NOTE!

The moving parts must be free of dirt and dust.

- If necessary, lubricate the moving parts as specified in the

lubrication chart.

ATTENTION!

Do not loop the belt around the adjustment screw of the

upper roll, as it could bend or damage the teeth.

WARNING!

Danger in case of insufficient qualification of per-

son!

Insufficiently qulified persons cannot assess the risks when

handling the machine and expose to serious or fatal injuries

to themselves ans others.

- Commissioning and all other work must only be carried out

by qualified personnel.

- Keep insufficiently qualified persons away from the work

area.