26

PRM FH | Version 1.04 | EN

Operation

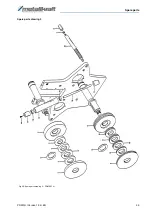

9.5.2Standard rolls

The ring bending machines are supplied with a set of standard rolls which,

when properly arranged, can bend most of the hot-rolled profiles available on

the market.

It is important that the rollers are well aligned on the machine and positioned in

the most advantageous position for each type of profile. This avoids excessive

force exerted by the machine and unnecessary twisting of the profile bar.

The stretching process of the rollers should be controlled in such a way that

the workpiece finds a good place between the rollers and can advance under

slight pressure.

In the case of the majority of profile bars, a considerable swelling will be no-

ticed inside the ring during the bending process, which is due to the compac-

tion. In this case, it is advisable to leave more play on the middle roller. If seve-

ral bending operations are required for one diameter, loosen the groove nut of

the centre roller to increase the roller thickness. This results in a better sliding

behaviour of the profile bar.

Fig. 19: Cross section of standard rollers, PRM 50 FH (left) and PRM 60 FH (right). Top: upper roller, bottom: lower rollers

162

16

2

152

152

21

5

215

21

5

215