32

PRM FH | Version 1.04 | EN

Maintenance, servicing and repair

- Hydraulic unit: Hydraulic Oil ISO HV 46 (10

μ

Filter)

- For lubrication: Grease ISO XMO

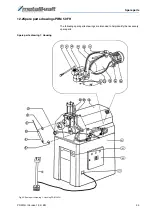

Some lubrication points are only accessible after the cover on the rear of the

unit has been opened.

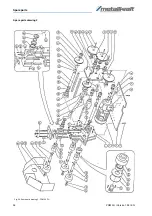

10.4Change and refill oil

Regularly check the hydraulic oil level and top up hydraulic oil if necessary. To

do this, pump the hydraulic oil with a pump through a filter from the reservoir

tank into the tank.

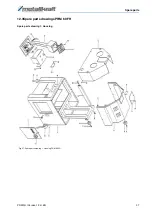

10.5Cleaning the electrical box

Step 1: Switch off the machine and disconnect the mains plug.

Step 2: Open the electrical box and clean the inside with a dry cloth. Never use

liquid cleaning agents!

Step 3: Check the connections to the various connections, fasten loose

connections.

Step 4: Close the door of the electrical box and connect the machine to the

mains. Start the machine and check all functions.

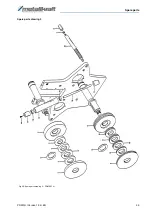

10.6List of potencial types of oil

No.

Equipment part

Interval

Lubricant

1

Cleaning the rolllers

daily

2

Lubricate the roller bearings

weekly

Grease, oil

3

Lubricating the guide roller bea-

rings

weekly

Grease

4

Axle bearings, cardan shafts

weekly

Liquid oil

5

Gearbox

weekly

Grease

6

Hydraulic tank, oil change

yearly

Hydraulic oil

7

Cleaning the electrical box

yearly

Type of oil

Category C (ISO CC 150)

Category H (ISO HV 46)

Category X (ISO XM 0)

AGIP

BLASIA 150

ARNOICA 46

GR MU EP 0

BP

ENERGOL GR-XP 150

BARTRAN HV 46

GREASE LTX0

GREASE LTX0-EP

CASTROL

ALPHA SP 150

HYSPIN AWN 46

SHEEROL APT 0

SHEEROL EPL 0

ELF

REDUFCTELF SP 150

HYDRELF DS 46

ROLEXA 0

EPEXA 0

ESSO

SPARTAN EP 150

UNIVIS N 46

BEACON EP 0

MOBIL

MOBIL GEAR 629

MOBIL DTE 15

MOBOL PLEX 45

Q8

GOYA 150

HAENDEL 46

REMBRANDT EP 0