8

PRM FH | Version 1.04 | EN

Safety

2.4 Personal protective equipment

Personal Protective Equipment is intended to protect people from compromi-

sing safety and health at work. Personnel must wear personal protective

equipment during the various operations on and with the machine, which are

specifically indicated in the separate sections of this manual.

The following section explains personal protective equipment::

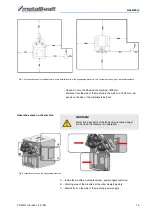

2.5 Safety markings on the ring bending machine

Various safety markings are attached to the ring bending machine

(Fig. 1),

which must be observed and followed.

Fig. 1: Safety markings - 1 Warning of dangerous electrical voltage - 2 Warning about rotating ma-

chine parts, danger of crushing during bending - 3 safety instructions

The safety markings attached to the ring bending machine must not be remo-

ved. Damaged or missing safety markings can lead to malfunctions, personal

injury and property damage. They are to be replaced immediately.

If the safety markings are not immediately recognizable and comprehensible,

the ring bending machine must be taken out of service until new safety mar-

kings have been made.

Ear protection

The goggles protect the eyes from flying parts and liquid

splashes.

Eye protection

The goggles protect the eyes from flying parts and liquid

splashes.

Protective gloves

The protective gloves protect the hands from sharp-edged

components as well as from friction, abrasions or deeper

injuries.

Safety shoes

The safety shoes protect the feet against bruising, falling

parts and slipping on slippery surfaces.

Protective clothing

The protective clothing is tight-fitting clothing with low tear

resistance.

1

2

3