Commissioning

RBM E | Version 1.07

21

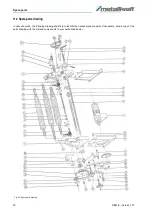

Standard operation

In order to be able to remove a bent workpiece from the machine, the lock of

the top roller must be released and the top roller must be removed from the

guide.

Fig. 14: Release lock of top roller

Step 1: Before starting the machine, check the locking of the top roller.

Step 2: Check the parallelism of the rollers with a gauge and spirit level.

Fig. 15: Check parallelism of rollers

Step 3: Turn on the main switch. The operating display lights up.

Step 4: Press the START button.

Step 5: Press the rollers with the pedals.

Step 6: Perform Bending.

Step 7: Stop the rollers after completing the bending process. Move the front

and rear rollers downwards.

Step 8: Loosen the lock of the upper roller, fold out the upper roller and remove

the workpiece. Use a crane to support the workpiece.

Step 9: Fold in the top roller and lock.

Step 10: Turn off the machine with the main switch.

DANGER

The unfolded top roller must not be overloaded by the work

-

piece. The workpiece must be supported by a crane.