10

RBM 305 | Version 2.02

Operation

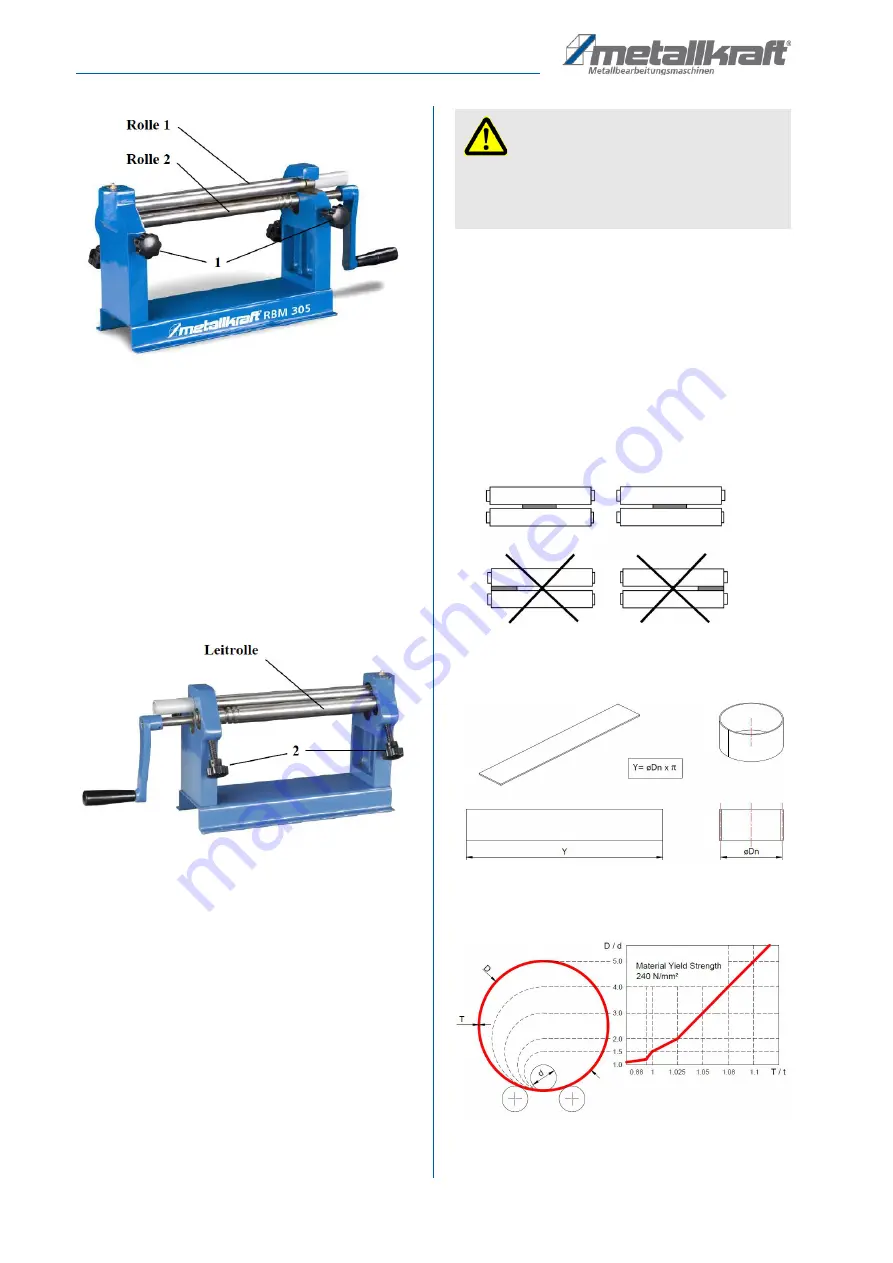

Fig. 7: Setting the sheet thickness

8.3 Adjusting the guide pulley

The guide roller (3) is adjusted by means of the two

rotary handles (2; Fig. 8). In order to achieve a greater

radius of curvature of the sheet, the rotary handles must

be unscrewed, screwed in for a smaller radius of curva

-

ture. To create straight tubes, the idler must be set paral

-

lel to the other rollers. For conical tubes, the idler must

be set at an angle. For this purpose, one of the rotary

handles (2) must be screwed in correspondingly deeper

than the other.

Fig. 8: Adjusting the guide pulley

8.4 bending process

Bending may only be performed by qualified personnel

experienced in these machines. All steps of bending,

pre-bending and conical bending must be carried out ex

-

tremely carefully. It should be noted that a small radius is

made by repeating the bending process several times;

Once too much bent, this step can not be undone.

Before editing

- Remove dirt and oil from the material.

- The material ends must be free of chips and burnt

residues.

- Burned material is harder at the points of separa

-

tion than in the remaining area.

- The material has to be level.

- It is recommended to make a stencil made of card

-

board or cardboard for the desired radius

Always work the workpiece in the center of the rollers

Fig. 9: Position workpiece in the middle of the rollers

Calculation of the workpiece length

Fig. 10: Calculation of the workpiece length

Bending chart

Fig. 11: Bending chart

WARNING!

It is not allowed to use profiles exceeding the specifi

-

cation strength. Do not work on more than one piece

at a time. Use the machine only for the intended pur

-

pose.