Operation

RBM 305 | Version 2.02

11

pre-bending

Pre-bending is the operation whereby the ends of the

material are bent to the same radius as the final radius.

As a result, the best results are achieved at full radii (eg

making tubes) or for operations where no flat ends are

desired.

Bending

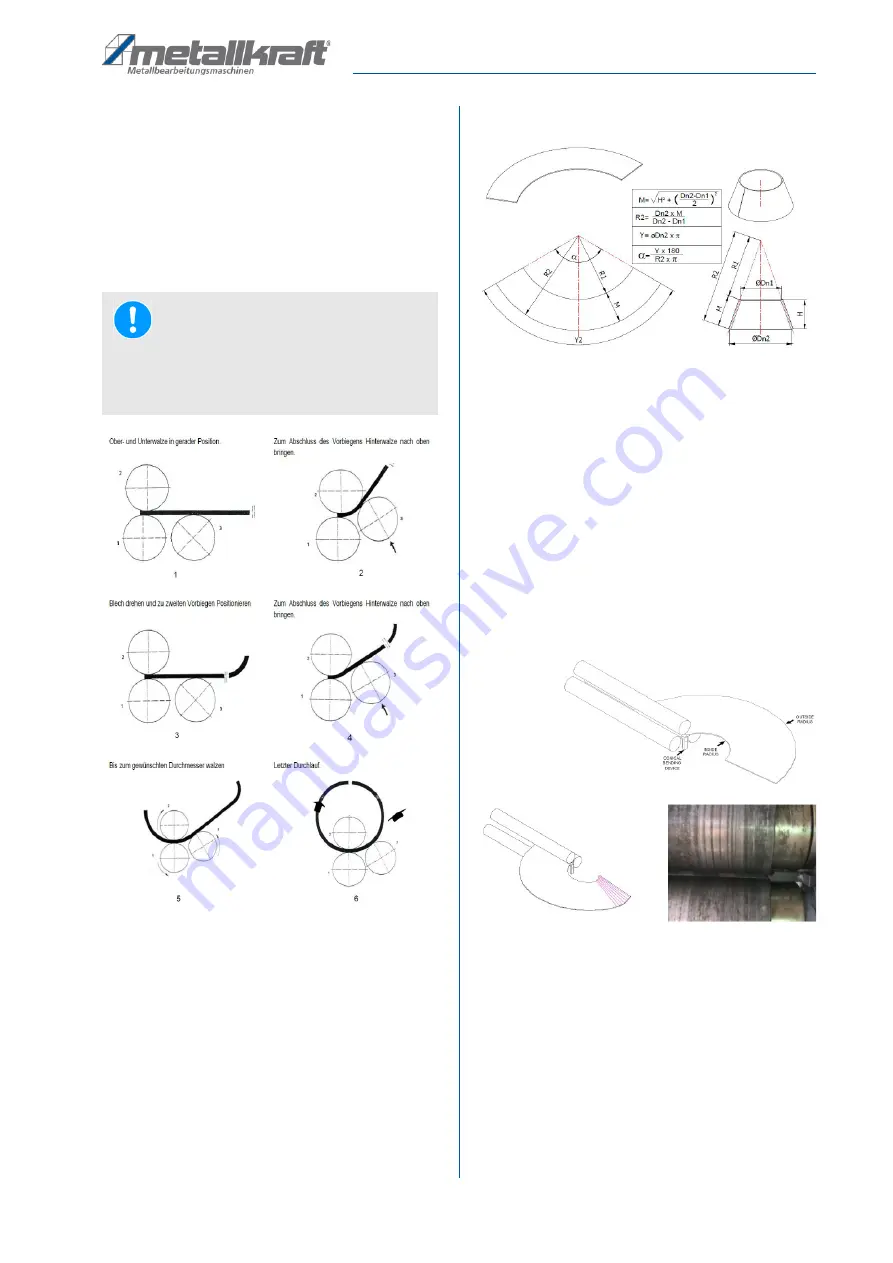

Fig. 12: Bending process

Conically bending

Conical bending is more difficult than normal bending.

The machine performance is reduced by 30% to 50%,

the conical bending capacity decreases by about 25%.

The material thickness must be reduced accordingly.

Calculation of the workpiece dimensions

Fig. 13: Calculation of the workpiece dimensions

Bending process

Step 1: Before conical bending, the sheet must be pre-

bent at the ends with parallel rolls.

Step 2: Then the machine has to be prepared for conical

bending:

Step 3: Adjust the guide roller in its angular position by

turning the handwheel so that the smaller dia

-

meter of the workpiece cone makes the roller

closer to the attraction rollers. As a result, a

narrower radius is created at the bend.

Fig. 14: Conically bending, preparation

The above-illustrated hardened bending tool holds the

material to be bent conically during the bending opera

-

tion.

NOTE!

The material hardens after each pass.

When processing stainless steel, several passes

must be made because this material is work harde

-

ning material.