Care, maintenance and repair

RBM 305 | Version 2.02

13

9.1 Cleaning and Maintenance

Regularly clean the bender with a soft, damp cloth.

Treat bare metal work surfaces with anti-rust spray and

clean the rollers regularly.

9.2 Repair

If the bender does not work properly, contact a dealer or

our customer service. The contact details can be found

in chapter 1.2 Customer Service.

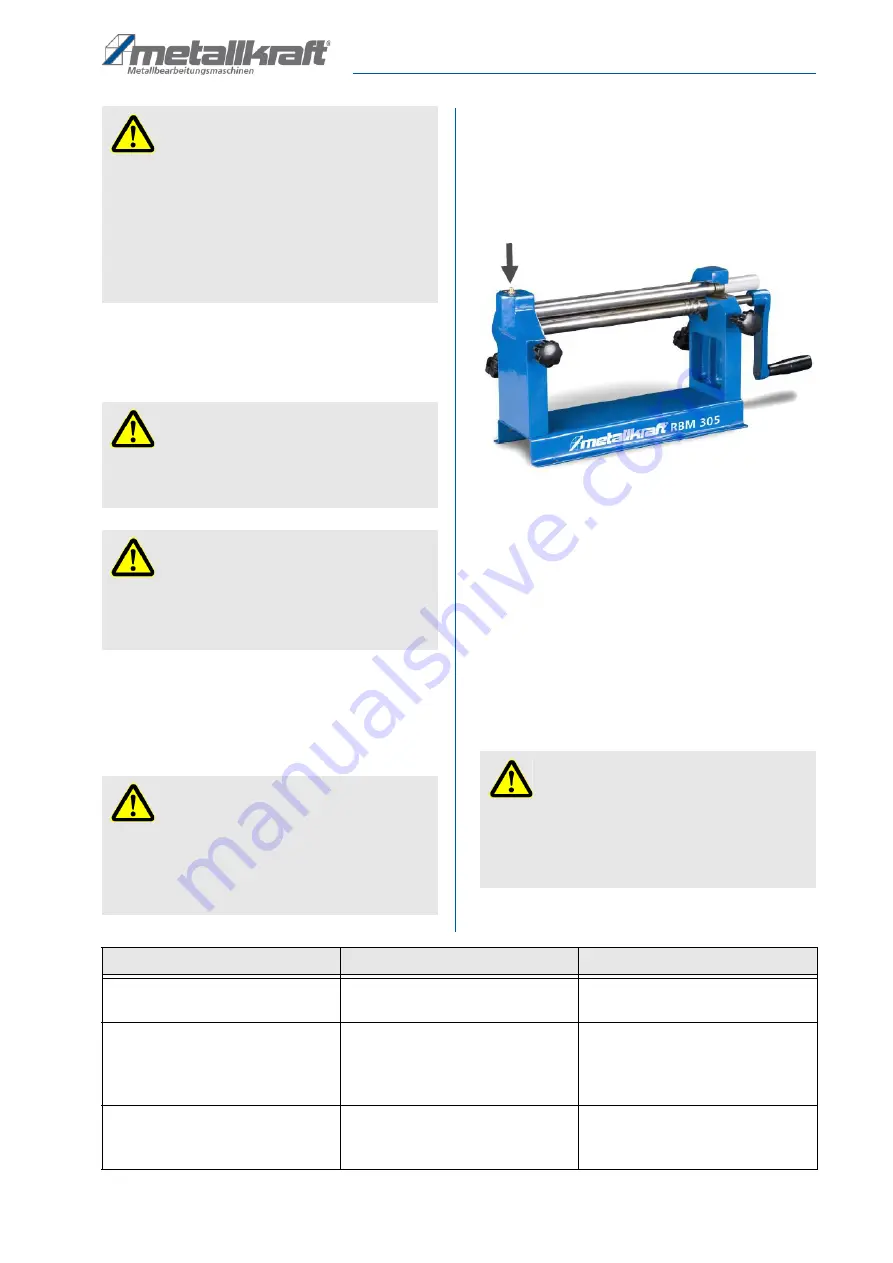

9.3 Lubrication schedule

Fig. 18: Lubrication schedule

If necessary, lubricate the gears. This is a conventional

grease to use without any special requirements.

At best use a grease gun that you attach to the grease

nipple.

Always remove debris from the rollers with a rag or the

like.

9.4 Troubleshooting

DANGER!

After servicing, maintenance and repair work, check

that all panels and guards are properly installed on

the machine again and that there is no more tools in

-

side or in the working area of the round bending ma

-

chine.

Damaged safety devices and parts must be repaired

or replaced by the customer service.

DANGER!

- Never use solvents to clean plastic parts or painted

surfaces. A surface release and consequential da

-

mage may occur.

DANGER!

The rollers must not be lubricated or oiled. You would

allow slipping of the material and thus trigger no ben

-

ding process. The rollers are always free from grease

and oil.

DANGER!

Repair work may only be carried out by qualified per

-

sonnel.

All protection and safety equipment must be reinstal

-

led immediately after completion of repair and main

-

tenance work.

DANGER!

If one of the following errors occurs, stop working

with the machine immediately. It could lead to serious

injuries. All repairs or replacement work may only be

carried out by qualified and trained specialist person

-

nel.

Fault

Possible cause

Remedy

The Plate rolling Machine does not

work.

1. The mechanics are broken.

1. Check the mechanics.

2. Contact the dealer.

The Plate rolling Machine does not

bend the material correctly.

1. The material thickness could be

wrong.

2. The wrong material has been in

-

serted.

1. max. Note plate thickness.

2. Insert only the correct material

The Plate rolling Machine does not

bend the materials as indicated in the

catalog.

1. The material thickness could be

wrong.

2. The mechanics are faulty.

1. Check the material to be bent.

2. Contact the dealer.