8

RBM 305 | Version 2.02

Operation

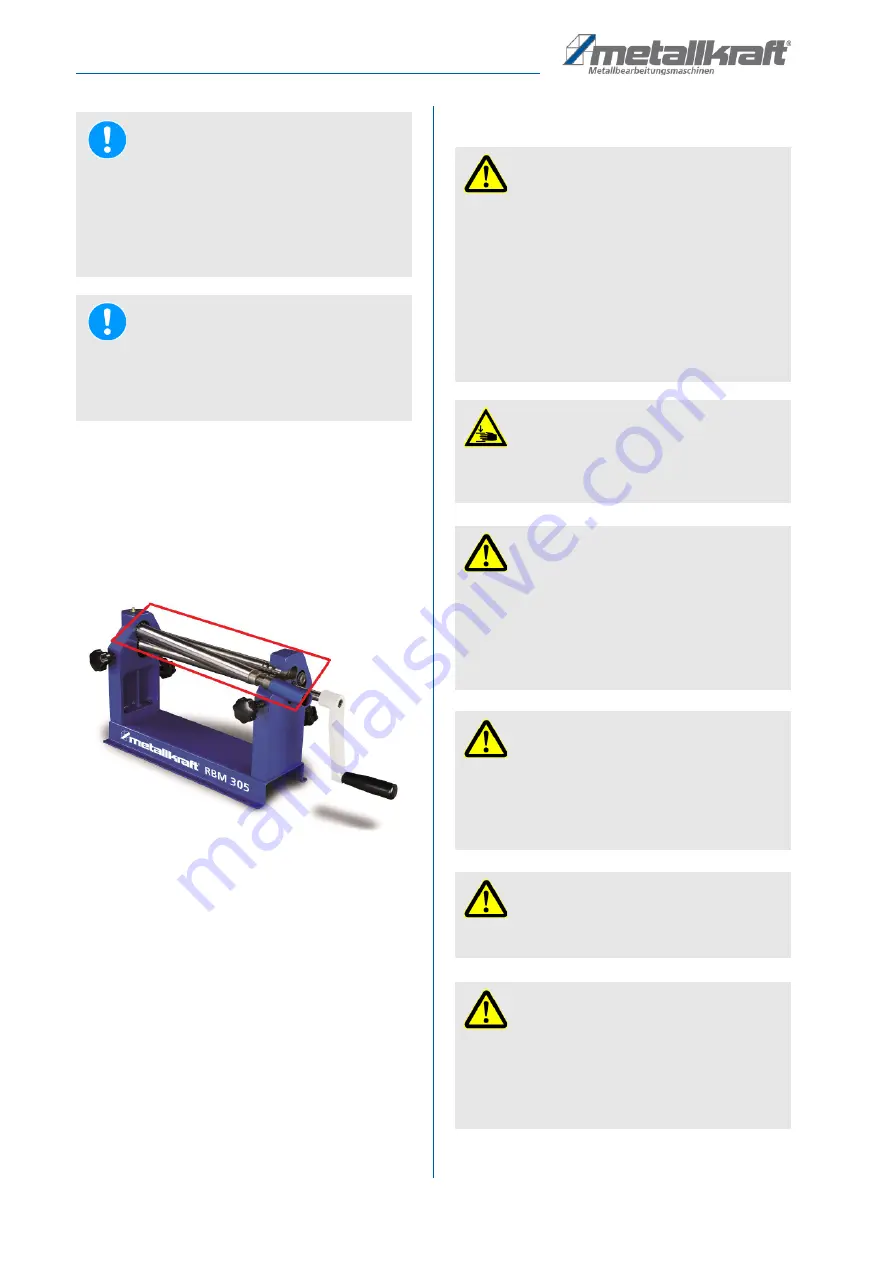

7.2 Hazardous Areas

The round bending machine is provided with the neces

-

sary protective equipment to prevent injuries that may be

caused by the gears. Another area of danger that must

be carefully observed during the machining process is

the range of rotation of the rollers.

Fig. 4: Danger area at the round bending machine

7.3 Lubricate bearings

Before using the machine for the first time, check and lu

-

bricate the bearings, see chapter "Cleaning and main

-

tenance".

8

Operation

NOTE!

After setting up, remove the protective agent from the

bare metal parts, which have been applied to protect

against rusting.

- Use usual solvents.

- No water, no nitrolic solvents or similar use!

NOTE!

The moving parts must be free from dirt and dust.

be free.

- If necessary, lubricate the moving parts as listed in

the Care and Maintenance section.

WARNING!

Danger due to insufficient qualification of per

-

sons!

Insufficiently qualified persons can not assess the

risks involved in handling the bending machine and

expose themselves and others to the risk of serious

injury.

- All work should only be carried out by qualified per

-

sons.

- Keep inadequately qualified persons out of the work

area.

WARNING!

Risk of Crushing!

The upper limbs must be kept away from the

machine during insertion and during machining of the

workpiece.

DANGER!

- Never perform any work on the bending machine

under the influence of alcohol, drugs or medication

and / or in case of fatigue or concentration-impai

-

ring illnesses.

- The bender may only be operated by a trained per

-

son.

DANGER!

Before using the round bending machine for the first

time, it is essential to lubricate the chains and bea

-

rings!

We assume no liability for damages due to improper

commissioning.

DANGER!

When operating the rollers: Do not drive the rol

-

lers against the lower stop!

DANGER!

- The operator should have a basic knowledge of this

type of machine.

- Operators should not wear wide garments, neck

-

laces, rings, etc. to prevent them from being pulled

into the running machine.