Service

03.05.2018

page 16

Service Plate rolling machine RBM 610-8 ; Version 1.05

©

20

18

GB

4.3

Working with the plate rolling machine

CAUTION!

Bending may only be performed by qualified personnel experienced on these machines.

All steps of bending, pre-bending and conical bending must be carried out extremely

carefully. It should be noted that a small radius is made by repeating the bending process

several times; Once too much bent, this step can not be undone.

4.3.1

Pre-bending

Pre-bending is the operation whereby the ends of the material are bent to the same radius as

the final radius. As a result, the best results are achieved at full radii z. B. in production of pipes)

or for operations in which no flat ends are desired.

Before editing:

The workpiece must be able to be fed in evenly from the upper and lower feed rollers.

Note that the material must be level.

Free the material surfaces from dirt and oil.

The material ends must be free of chips, chisels and burnt residues.

Note that burned material is harder at the points of separation than in the remaining area.

It is recommended to make a stencil of cardboard or cardboard from the desired radius as a

reference for the bending process.

Adjust the distance between the feed roller with the handwheel to adjust the lower roller so

that the workpiece is drawn in continuously with evenly distributed force.

Make sure that the rear roller is parallel to the feed rollers, if necessary, readjust them using

the handwheels.

WARNING!

Only bend workpieces whose material is known to you and check whether it is suitable

for cold forming.

Do not bend brittle materials that can break or splinter parts.

For processing

‘

Be sure to always work in the middle of

the rollers.

‘

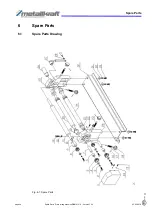

Follow the steps shown below for round

b "sheet metal position for round

bending" on page 18.

‘

Rotate the crank to selectively retract or

move the workpiece through the feed

rollers.

Fig.4-2: Processing