16

UB 10 | Version 2.01

Care, maintenance and repair

Turn the spiral around as long as the bending segment

allows it. Take out the stop and the segment and place

them in the hole for the second bend and finish the spiral.

9.2 Heating pipe bending roll set

For cold bending of heating pipes of size G3 / 8 ", G1 /

2", G3 / 4 ". For a curvature of a heating pipe, a heating

pipe bending roll set is required (larger and smaller rolls).

The large roll is used as the middle and the material is

bent with it. The procedure is similar to the normal ben

-

ding rollers.

Fig. 41: Heating tube bending rolls set

9.3 Clamp

It is used for mounting the dismantled bending unit of the

UB 10. For this you need three screws. The clamping

plate must be firmly mounted to an anchored workbench.

Fig. 42: Clamp

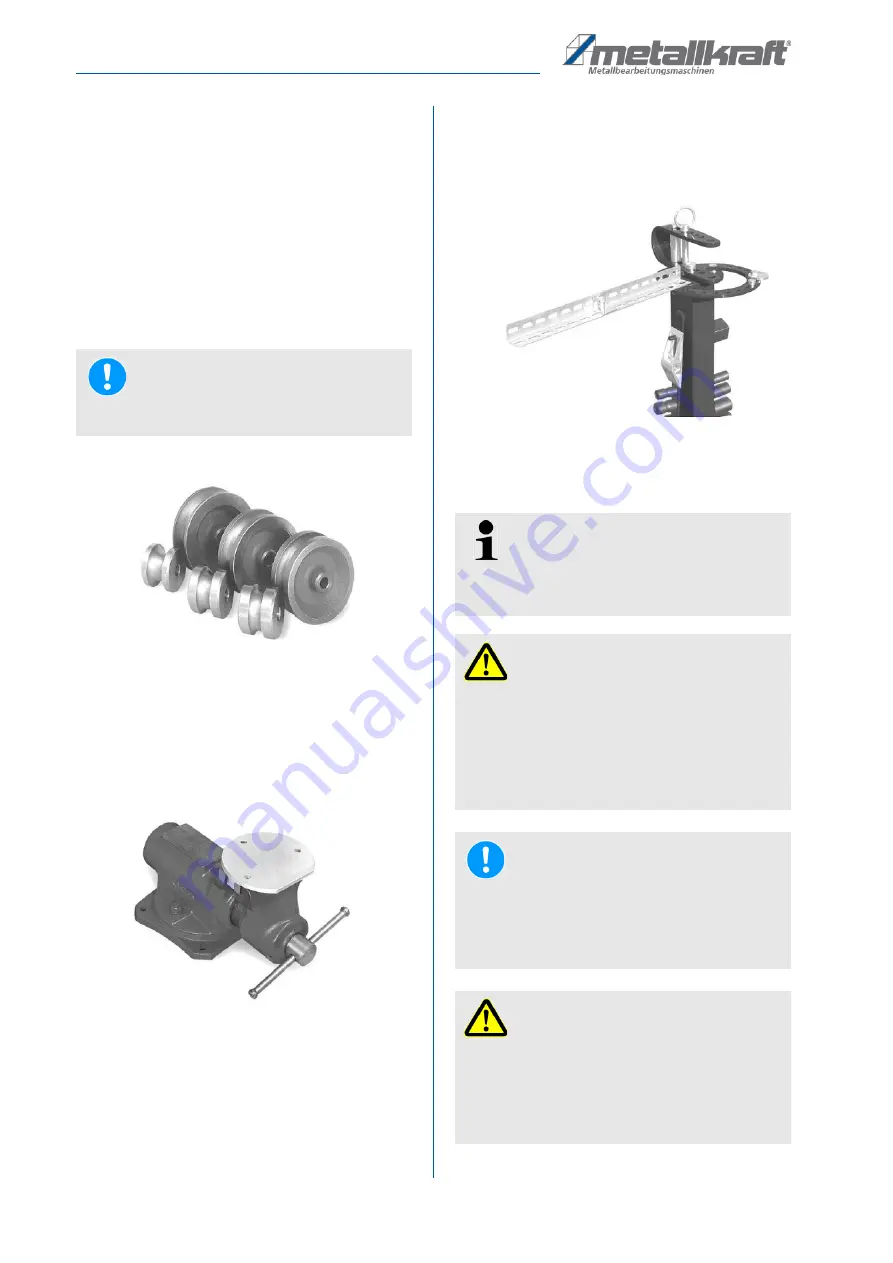

9.4 Adjustable stop 10-200

It is a universal, adjustable stop to produce material of the

same length for a series of bends. Use a screw and a nut

to secure the fence in the second or third hole.

Then turn the stopper so that the curved material is per

-

pendicular to the outer side of the stopper. Fix the stopper

so that the material is parallel to the underside of the stop

-

per. The adjustable stop can be fixed from both sides.

Fig. 43: Adjustable stop

10 Care, maintenance and repair

NOTE!

The pipe must not be bent more than 180 °, other

-

wise it will jam in the bending roller.

Tips and recommendations

To ensure that the bending machine is always in

good operating condition, regular care and main-

tenance work must be carried out.

DANGER!

Danger due to insufficient qualifica-

tion of persons!!

Insufficiently qualified persons can not assess the

risks involved in maintenance work on the machine

and expose themselves and others to the risk of

serious injury.

- All maintenance work should only be carried out by

qualified persons.

NOTE!

Before servicing and maintenance the Universal

Bending Machine, the maintenance instructions must

be carefully read. The handling of the Universal Ben

-

ding Machine is only permitted to persons who are

familiar with the Universal Bending Machine.

DANGER!

After servicing, maintenance and repair, check that all

panels and guards are properly installed on the machine

and that there is no more tool inside or in the working

area of the universal bending machine. Damaged safety

devices and equipment must be repaired or replaced by

the customer service.