18

OPERATION MANUAL

4.4. COMMISSIONING CHECK LIST.

Before starting the machine the following checks must be carried out.

q

Installation and machine preparation has been performed according to the manuals instructions.

q

Fill the oil reservoir with 46 grade hydraulic oil and ensure that the oil filter breather cap is fitted

q

All grease nipple points have been lubricated.

q

Electrical earth fitted and power circuits, switches, and foot-pedal checked.

q

Check power connections and any damage to any wiring.

q

Setup rear sensors

q

Check pump rotation.

q

Test safety operation, Estop, rear sensors, stop button etc.

q

Test controller operation.

q

Test all mechanical operation on the machine including blade and back gauge travel and limit

switch operation.

q

Calibrate x axis on controller.

q

Test cut material and check quality of cut

q

Tools, equipment and personnel are clear of the machine.

q

Operation Manual on how to operate the machine has been read.

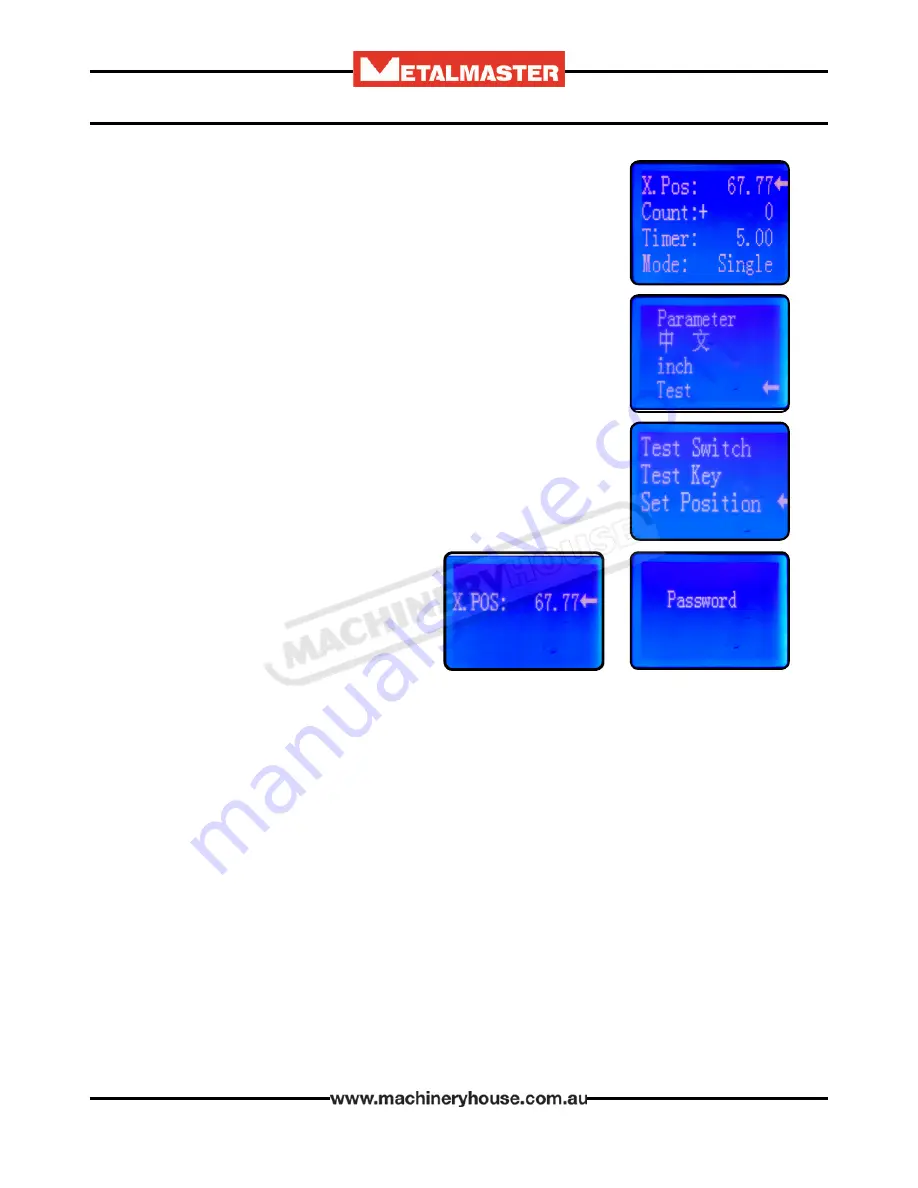

4.3 CALIBRATE “X” AXIS ON CONTROLLER

Before operating the machine the “X” axis needs to be checked. The

following is that process.

1 Cut a piece of material and measure it with a vernier. Check the

dimension against the x position on the readout. If the measurement is

the same then the “X” axis has been set. If they are different then do the

following.

2 With power off depress the red button on the controller and turn on

the power key.

3 Arrow down to test and press ok

4 Arrow down to set position and press ok. The controller will ask you

to enter the access code below..

ACCESS CODE IS 258

5 After entering the access code delete size on screen and enter new size

6 Press ok to save changes

7 Press ESC 3 times to exit out to normal screen.

Page 18

Instructions Manual for HG-4012 (S948)

12/02/2018