26

OPERATION MANUAL

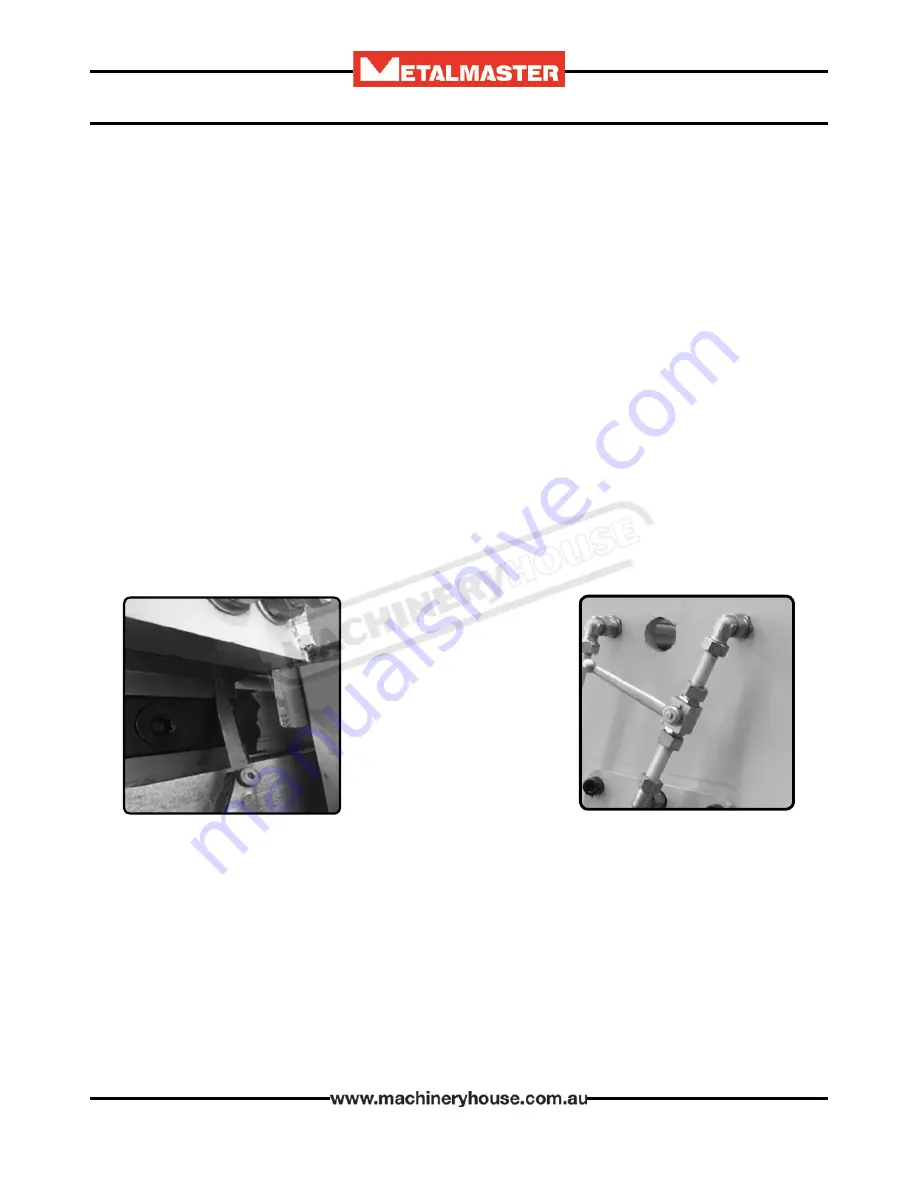

6.5. BLADE PARALLEL ADJUSTMENT.

The following information also applies when fitting new or sharpened blades.

This is a two man job where one will need to check the blade clearance with a feeler gauge (Fig 6.5)

from the rear of the machine while the other adjusts the blade holder setting.

q

The clearance is checked across the full length of the blades.

q

Use feeler gauges, to test the clearance.

q

According to the test adjust the clearance.

TO CHECK THE CLEARANCE AT SET INTERVALS ON THE BLADE.

q

Set the selector control on the control box to normal operation function.

q

Depress the foot pedal and move the blade to the maximum down stroke position then shut off

the ball valve in Fig 6.6 to hold the down stroke position.

q

Release the ball valve slowly to allow the upward movement of the blades to check the

clearance at set intersection intervals of the blades.

q

Once the clearances are equal and parallel tighten all fasteners and locknut’s and release the

ball valve fully.

q

This operation may be required to be repeated until clearances are correct and equal.

Fig. 6.5

Fig. 6.6

On completion of the blade setting, re-check the electrical system and then press the foot pedal and

allow the machine to continually cycle for two minutes. Test the cutting at maximum rated capacity.

Check the hydraulic system for oil leaks. Replace and secure all covers on completion of

commissioning

Page 26

Instructions Manual for HG-4012 (S948)

12/02/2018