12 Intelligent Products—2551J and 2551TJ Plug-In Intelligent Photoelectronic Smoke Detector

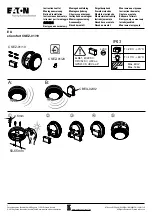

Functional Test Magnet (M02-04-01)

This detector can be functionally tested with a test magnet. The test

magnet causes the electronic simulation of smoke in the sensing chamber,

and tests the detector’s electronics and connections to the control panel.

1.

Place the magnet against the cover opposite the test module socket to

activate the test feature (Figure 4).

2.

The LEDs should latch on within 30 seconds indicating alarm and

annunciating the panel.

te s ts w c 3

T e st M od ule

S o cket

L E D

P ush recessed te st sw itch

w ith a 0.1 in. m ax. diam eter tool.

T e st M a g n et

P a in te d

S u rfa c e

LE D

Figure 4: Views Showing Position of the Test Magnet

(model 2551TJ shown)

Sensitivity Test Module (MOD400R)

The MOD400R is used with your Digital Multimeter (DMM) or voltmeter

to check the detector sensitivity as described in the MOD400R’s manual.

If the detector’s sensitivity limits or the MOD400R limits do not appear on

the back of the detector, the MOD400R is not suitable for field sensitivity

testing of that unit.

Smoke Entry Aerosol Generator (Gemini 501) per NFPA 72-National

Fire Alarm Code

The field test tool is the Gemini model 510 aerosol generator.

1.

Set the generator to represent 4 to 5%/ft obscuration as described in

the Gemini 501 manual.

2.

Using the bowl-shaped applicator, apply aerosol until unit alarms.

This test only verifies proper operation of the detector, and is not used

to test sensitivity.

Testing the 2551J

and 2551TJ

Summary of Contents for 2551J

Page 2: ...2 Intelligent Products 2551J and 2551TJ Plug In Intelligent Photoelectronic Smoke Detector ...

Page 6: ...6 Intelligent Products 2551J and 2551TJ Plug In Intelligent Photoelectronic Smoke Detector ...

Page 10: ...10 Intelligent Products 2551J and 2551TJ Plug In Intelligent Photoelectronic Smoke Detector ...