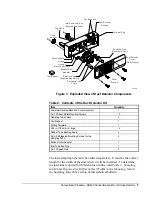

16 Conventional Products—DH400 Conventional Air Duct Smoke Detector

The DH400 detectors are designed for easy wiring. The housing provides

a terminal strip with clamping plates.

To make wiring connections:

1.

Strip about 3/8 inch of insulation from the end of the wire. Use the

strip gauge molded into the base for ease of wiring to terminals.

2.

Slide the bare end under the plate.

3.

Break the wire at each terminal to ensure that the connections are

supervised (Figure 4).

Note: Do not loop the wire over the clamping plate.

4.

Tighten the clamping plate screw.

DH400 detectors are designed to operate with 12 or 24 VDC UL Listed

2-wire compatible control panels. Alarm current must be limited by the

control panel to 100 mA or less.

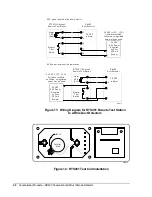

The IDC zone wiring of the detector base should be checked before the

detector heads are installed in them. To make this possible, this base

contains a special spring-type shorting jumper. After a detector base is

properly wired and mounted on an electrical box, make sure that the

jumper is in contact with the base of Terminal 3. This temporary

connection shorts the negative-in and negative-out leads and permits the

wiring of the IDC to be checked for continuity.

Once all the detector bases have been wired and mounted and the IDC,

power, and optional releasing device control wiring has been checked, the

detector heads may be installed in the bases. The shorting jumper in the

base will disengage when the detector head is turned into place.

Note: Terminals 2, 3, and 5 do not use looped wire under terminals.

Break wire run to provide system supervision of connections.

T h is

N ot This

w irg u id e

Figure 7: Electrical Connections

Wiring the DH400