Conventional Products—DH400 Conventional Air Duct Smoke Detector 19

Testing and Maintenance

Procedures

Test and maintain duct detectors as recommended in NFPA 72-National

Fire Alarm Code. The tests contained in this manual were devised to

assist maintenance personnel in verification of proper detector operation.

Before conducting these tests, notify the proper authorities that the smoke

detection system will be temporarily out of service.

After a detector is set into alarm by one of the following test methods, and

the alarm activating device is removed from the detector, the system

should be reset at the control panel before testing any additional detectors.

After all testing is complete, notify the proper authorities that the system is

back in service.

All detectors must be tested after installation and periodically thereafter.

Testing methods must satisfy the authority having jurisdiction. Detectors

offer maximum performance when they are tested and maintained in

compliance with NFPA 72-National Fire Alarm Code.

After conducting these tests, record the appropriate information in the

Sample of Test Log section of this technical bulletin.

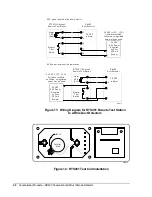

To verify sufficient sampling of ducted air, use a manometer to measure

the differential pressure created from airflow across the sampling tubes.

The pressure should measure no less than 0.01 inches of water and no

greater than 1.20 inches of water.

1.

Visually identify any obstructions to determine if smoke is capable of

entering the sensing chamber.

2.

Plug the exhaust and inlet tube holes to prevent ducted air from

carrying smoke away from the detector head.

3.

Blow smoke such as cigarette, cotton wick, or punk directly at the

head to cause an alarm.

4.

Remember to remove the plugs after this test, or the detector will not

function properly.

Testing Duct

Detectors

Testing Smoke

Entry

Airflow

Smoke Response