Conventional Products—DH400 Conventional Air Duct Smoke Detector 21

1.

Look for the presence of the flashing red LEDs through the

transparent housing cover.

2.

The LEDs should flash approximately every ten seconds.

Note: This standby test does not not indicate the detector is in alarm,

rather, that the detector is properly wired, receiving power and

is ready to transmit an alarm.

1.

Remove the detector head from the duct housing.

2.

The detector head is removed by turning it counterclockwise about

10 degrees (Figure 11).

3.

The system control panel should indicate a trouble condition.

4.

Replacing the detector head should clear the trouble indication.

1.

Place the painted surface of the magnet into the test locator molded

into the side of the housing (Figure 9).

2.

Verify the red alarm LEDs on the detector latch on, as should any

accessories such as the RA400Z and RTS451.

3.

Verify system control panel alarm status and control panel execution

of all intended auxiliary functions such as the fan shutdown damper

control.

4.

Reset the detector by the system control panel.

The RTS451 remote test station facilitates test of the alarm capability of

the duct detector as indicated in the RTS451 Remote Test Station Technical

Bulletin in the Intelligent Products section of this manual.

Note: The DH400 duct detector must be reset by the system control panel.

To install the RTS451:

1.

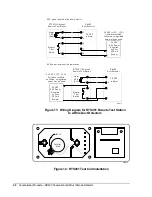

Connect the device (Figure 10).

2.

Wire runs must be limited to 25 ohms or less per interconnecting wire.

3.

Place the test coil in the detector housing with the arrow facing up and

pointing toward the detector (Figure 11).

4.

Attach the test coil leads to the housing terminals as shown.

Polarity is not important.

5.

Firmly screw the bracket in place over the test coil.

Testing

Standby, Alarm,

and Sensitivity

Standby Test

Trouble Test

Testing Alarms

M02-04-00

Magnet Test

RTS451 Remote

Test Station