1

2

GB

8

Page

GB

Practice personnel / technicians

Description of function

8. Description of function of the compressor

1

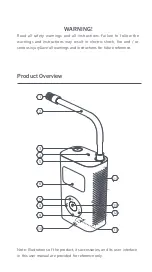

Compressors without a membrane dryer (Light models):

The compressor power unit sucks in air from the outside through

the air intake filter (1). The air is compressed in an oil-free

compression chamber (2), then passes through a delivery hose (3)

and is forced through the non-return valve (4) into the pressure

tank (5). The air flow is regulated by a valve plate that allows air

flow in one direction only.

Compressors with a membrane dryer:

The compressor power unit sucks in air through the air intake

filter (1). The air is compressed in an oil-free compression chamber

(2), then is forced through the cooler (6) which cools down the

compressed air and thus forms condensate water.

The condensate is trapped by a 5 mµ filter (7) located below the

cooler. A second 0,01 mµ filter (8) blocks further water droplets

to ensure high quality, clean air. This double filtration system

has a semi-automatic drain system that empties the small filters

receivers everytime pressure is discharged.

The clean compressed air then passes through the membrane

dryer (9) where residual humidity is removed and the compressed

air reaches an average dew point value of -35°C (at 7 bar). Dry,

compressed air is delivered to the air receiver through a hose that

connects the dryer to the non-return valve (5).

The entire system is controlled by the pressure switch (10)

that regulates the ON/OFF mode of the unit. Every time the

compressors reaches the cut out pressure, it switches off and

residual compressed air in the delivery pipe system is vented out

by a solenoid valve (for compressors without air dryer) or by the

membrane dryer (9) - for compressors with air dryer.

9. Description of the function of the membrane dryer

2

Filtered air enters the membrane dryer and water droplets are

collected on the membrane fibres. While the dried air is delivered

to the receiver, a small amount of this dried air is purged back

through the membrane to sweep away the water droplets around

the fibers. The moisture is then delivered to the outside through

the rinsing nozzles of the membrane dryer. Since this purge

cycle is continuous, the membrane dryer can operate without

interruptions or efficiency reduction.

Membrane dryers do not require any maintenance because there is

no water adsorption or adsorbing material.

Periodical maintenance needs to be performed on the double

filtration system (0,5 µm, 0,01 µm) before the membrane dryer.

Filters cartridges must be replaced once a year. Maintenance kits

are available at METASYS.