46

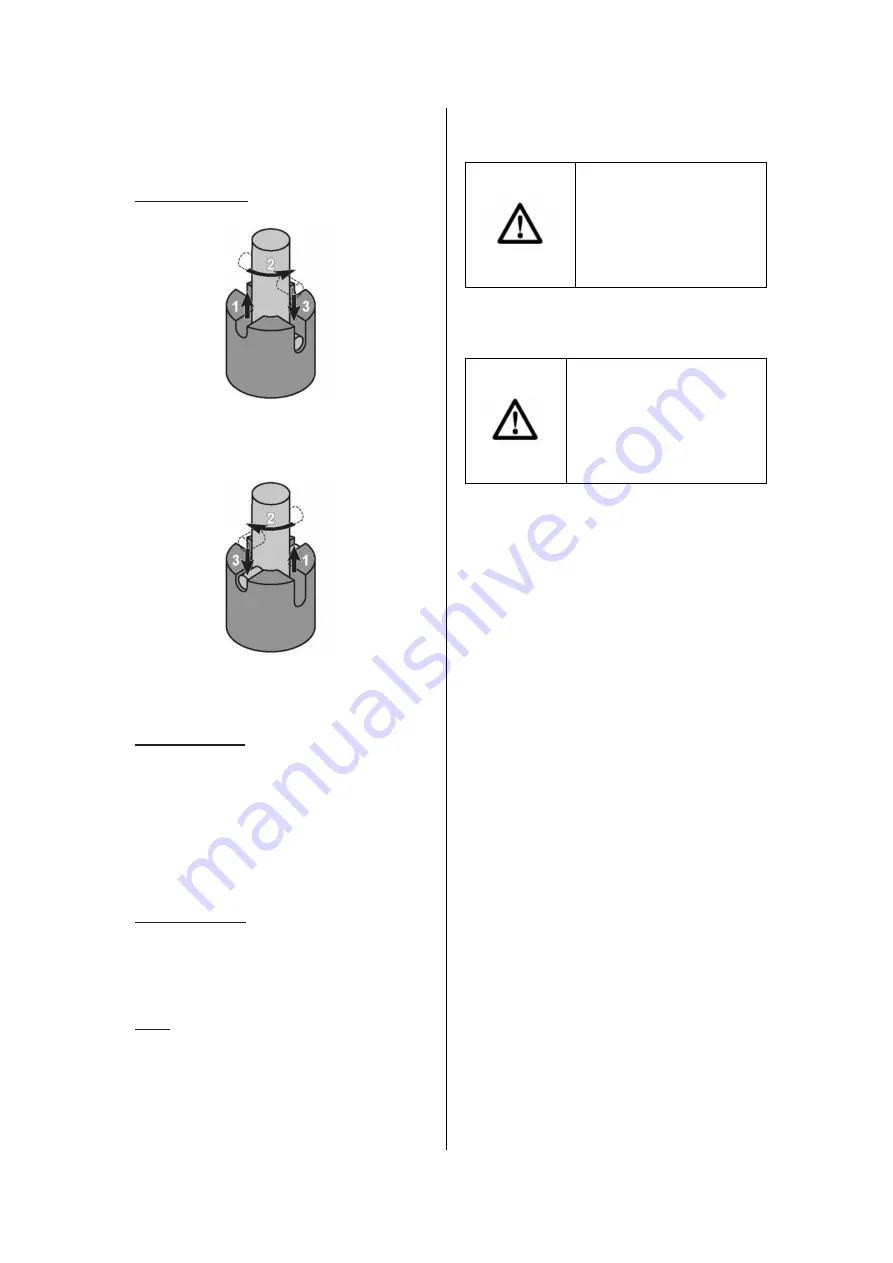

Spindle Lock Head Lock_down

Description of Selected Functions

Head Lock-down:

Align pin with deep groove to lock cutting

head.

Align pin with shallow groove to unlock

cutting head.

Guard operation:

When the Handle is lowered, the Lower Guard

raises automatically. When the Handle is

raised the Lower Guard returns to its safety

position. Keep hands clear of the Blade when

the Handle is lowered. Do not interfere with

the proper movement of the Lower Guard.

Slide Lock Knob:

Tighten this to prevent the cutting head from

sliding back and forth for chopping cuts.

Loosen this to allow the cutting head to slide.

Note: Additional functions are explained

elsewhere in the manual.

INSTRUCTIONS FOR USE

Read the ENTIRE

IMPORTANT SAFETY

INFORMATION section at

the beginning of this

manual including all text

under subheadings therein

before set up or use of this

product.

TOOL SET UP

TO PREVENT SERIOUS

INJURY FROM

ACCIDENTAL

OPERATION:

Turn the Power Switch of the

tool off and unplug the tool

from its electrical outlet before

performing any procedure in

this section.

TO PREVENT SERIOUS INJURY: DO NOT

OPERATE WITH ANY GUARD DISABLED,

DAMAGED, OR REMOVED. Moving guards

must move freely and close instantly.

Using the Workpiece Extension Supports

1. The Table Extensions are inserted into

each side of the Table, and locked in place

using the Wing Screws.

2. When properly installed, the upper face of

the Table

Extensions are level with the

Table, and provide a wider support surface

for the workpiece.

3. Support the workpiece to be level with the

table, and so that after the cut is made the

cut off pieces will not fall. Use sawhorses

or other supports (not included) to support

longer workpieces.

4. If the workpiece is not level, you will make

an unintentional bevel cut in the material.

If the workpiece is not supported, it will bind

the blade and may cause the material to

kick back, potentially causing injury.