12

Lubricating Your Slicer

NOTE:

Use only the tasteless oil provided or white Vaseline oil.

Do not

use vegetable oils!

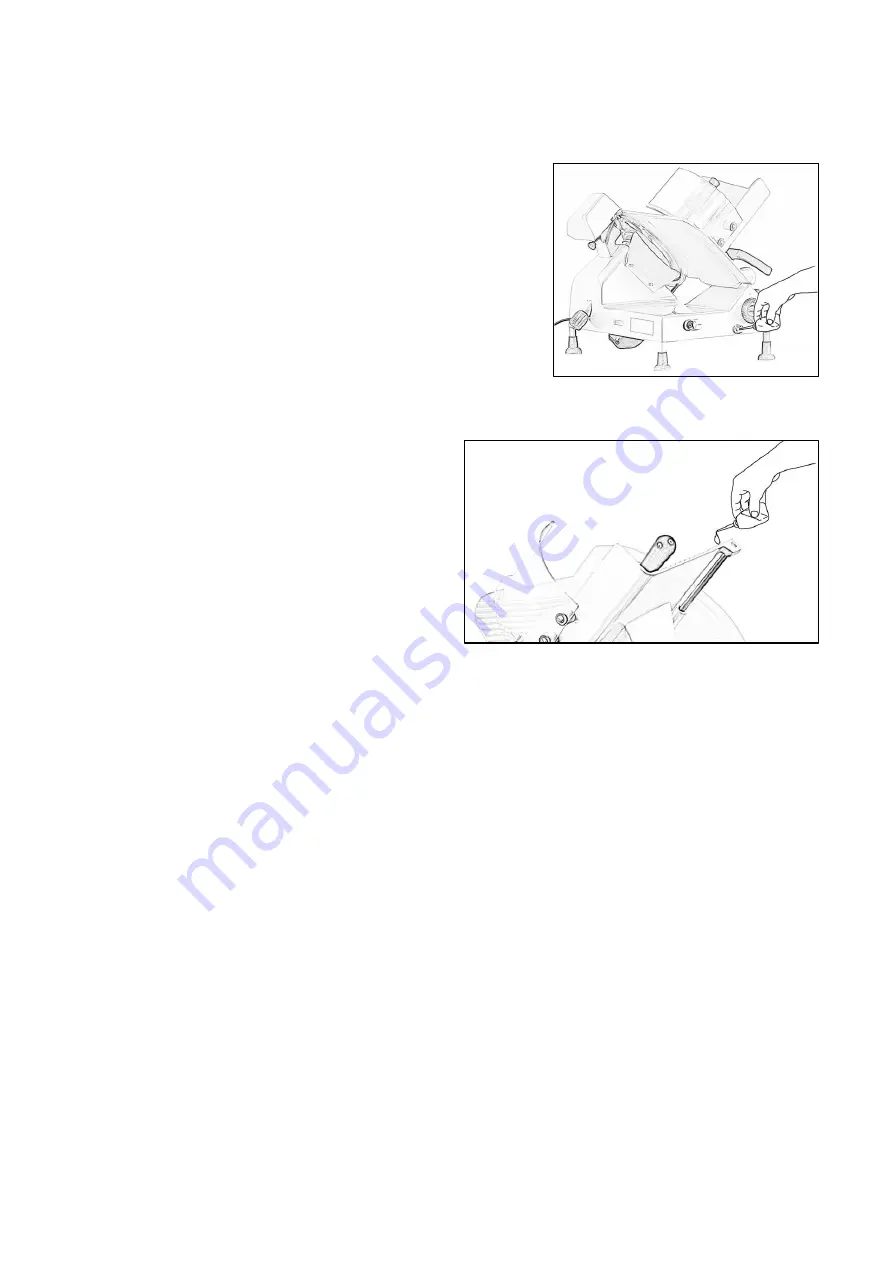

Lubricating the bottom runner guide bars (weekly)

•

Move the carriage as close as possible to the operator

•

Insert the oiler in the special hole/lubricating screw

•

Squeeze the oiler so that a small amount of oil goes

into the hole

•

Remove the oiler and slide the carriage 3 to 4 times.

NB: Not all machines are equipped with a lubricating screw.

If so, lift the machine and lubricate the carriage bar directly.

Lubricating the transversal guide rods of the table

and end device (weekly)

•

Put a small amount of oil on the rod and slide

the group 3 to 4 times.

•

Clean as necessary removing any excess oil.

Slicer Safety Tips

To avoid serious personal injury:

•

NEVER

touch the slicer without training and authorisation from your supervisor or if you are under the age of

18. Read this instruction manual first.

•

ONLY

install the slicer on a level, non-skid surface that is non-flammable and located in a clean, well-lit work

area and away from children and visitors.

•

NEVER HOLD THE FOOD PRODUCT WHILE SLICING

. Hold only the end device handle while slicing.

•

BEFORE CLEANING, SHARPENING, SERVICING, OR REMOVING ANY PARTS

always turn the slicer off, turn the

thickness selection knob clockwise until it stops and unplug power cable.

•

NEVER

touch rotating knife.

•

ALWAYS

keep hands clear of all moving parts.

•

ALWAYS

turn slicer off, turn the slicer thickness selection knob clockwise until it stops.

•

NEVER

place the power cord over the unit.