2.9.2003

Rev. 1.0

Adjustment instructions

32

6.2

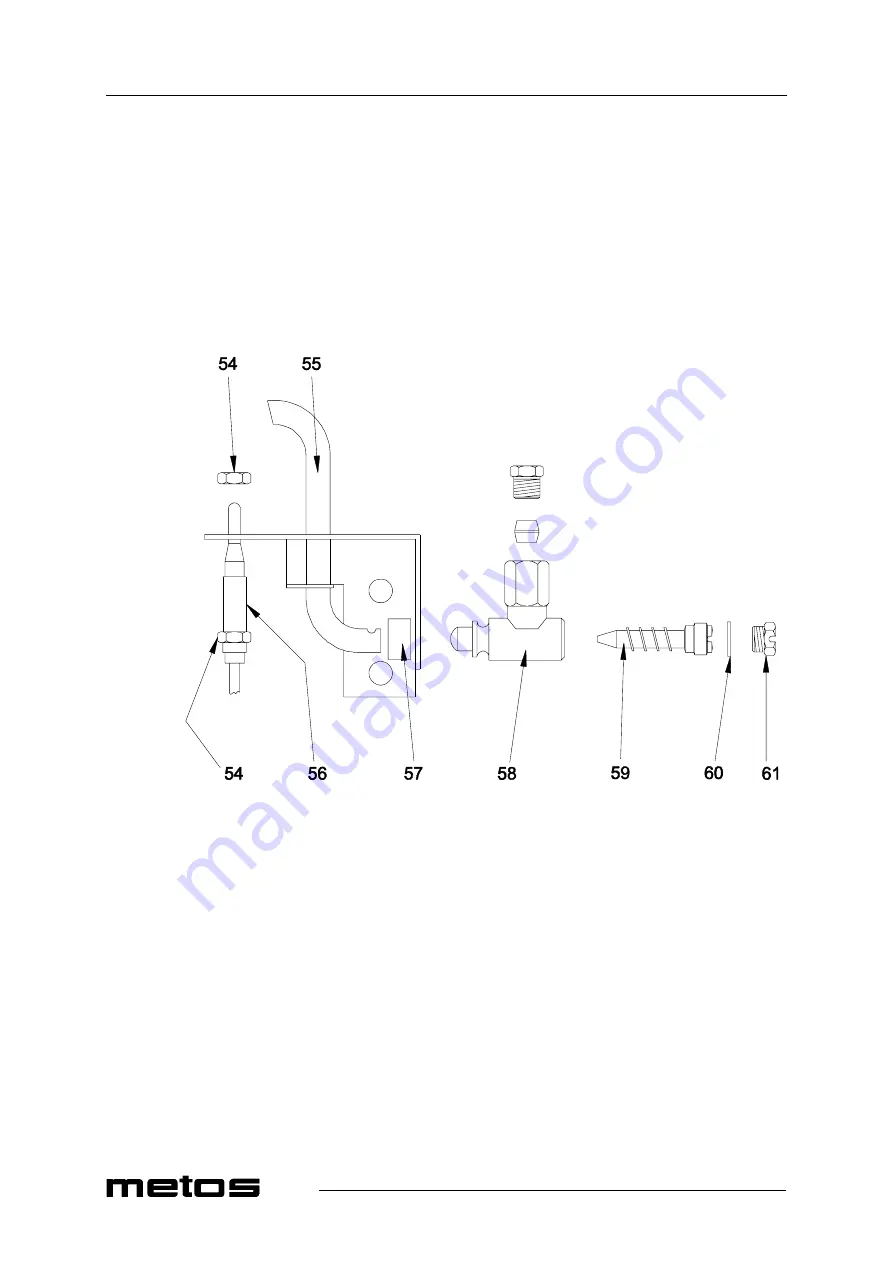

Replacing the nozzle of open burner pilot flames

•

Unscrew the sealing screw (item 61 in Fig. 12) using an 11-mm spanner, and re-

move it;

•

unscrew the nozzle (item 59) with a flat-blade screwdriver and remove it;

•

fit a suitable nozzle and screw it down completely (see

"Table 2: burner specifica-

tions"

);

•

adjust primary air to the pilot flame by moving the ring shown as item 57;

•

the pilot flame should be blue and it should fully wrap up the thermocouple; oth-

erwise, check that you have fitted the right nozzles.

Fig. 12

54.

Thermocouple fixing nut

55.

Pilot flame top

56.

Thermocouple

57.

Air register ring

58.

Pilot flame body

59.

Nozzle

60.

Gasket

61.

Sealing screw

Summary of Contents for 72/02CG

Page 2: ......

Page 4: ...30 7 2003 Rev 1 0...

Page 10: ...2 9 2003 Rev 1 0 Safety 4...

Page 14: ...2 9 2003 Rev 1 0 Functional description 8...

Page 34: ...2 9 2003 Rev 1 0 Installation 28...

Page 44: ...2 9 2003 Rev 1 0 Adjustment instructions 38...

Page 48: ...2 9 2003 Rev 1 0 Troubleshooting 42...

Page 50: ......

Page 51: ...SC00414 wiring diagram 74 02CGE 76 02CGE 3 N PE 400V 50 60 Hz...

Page 52: ...6SC00473 wiring diagram 74 02CGE 76 02CGE 74 02CTGE 3 PE 230V 50 60 Hz...

Page 53: ...SC00415 wiring diagram 76 02CGGE 1 N PE 230V 50 60Hz...

Page 54: ...SC00413 wiring diagram 76 02CGEE 3 N PE 400V 50 60Hz...

Page 56: ...2 9 2003 Rev 1 0 Technical specifications 74 Installation and connection drawing 72 02CG...

Page 57: ...2 9 2003 Rev 1 0 Technical specifications 75 Installation and connection drawing 72 02TCG...

Page 58: ...2 9 2003 Rev 1 0 Technical specifications 76 Installation and connection drawing 74 02CG...

Page 59: ...2 9 2003 Rev 1 0 Technical specifications 77 Installation and connection drawing 74 02TCG...

Page 60: ...2 9 2003 Rev 1 0 Technical specifications 78 Installation and connection drawing 74 02CGG...

Page 61: ...2 9 2003 Rev 1 0 Technical specifications 79 Installation and connection drawing 74 02CGE...

Page 62: ...2 9 2003 Rev 1 0 Technical specifications 80 Installation and connection drawing 76 02CG...

Page 63: ...2 9 2003 Rev 1 0 Technical specifications 81 Installation and connection drawing 76 02TCG...

Page 64: ...2 9 2003 Rev 1 0 Technical specifications 82 Installation and connection drawing 76 02CGG...

Page 65: ...2 9 2003 Rev 1 0 Technical specifications 83 Installation and connection drawing 76 02CGGE...

Page 66: ...2 9 2003 Rev 1 0 Technical specifications 84 Installation and connection drawing 76 02CGE...

Page 67: ...2 9 2003 Rev 1 0 Technical specifications 85 Installation and connection drawing 76 02CGEE...

Page 72: ......