DOMITOR DM/DB

GB - 16

Safety devices

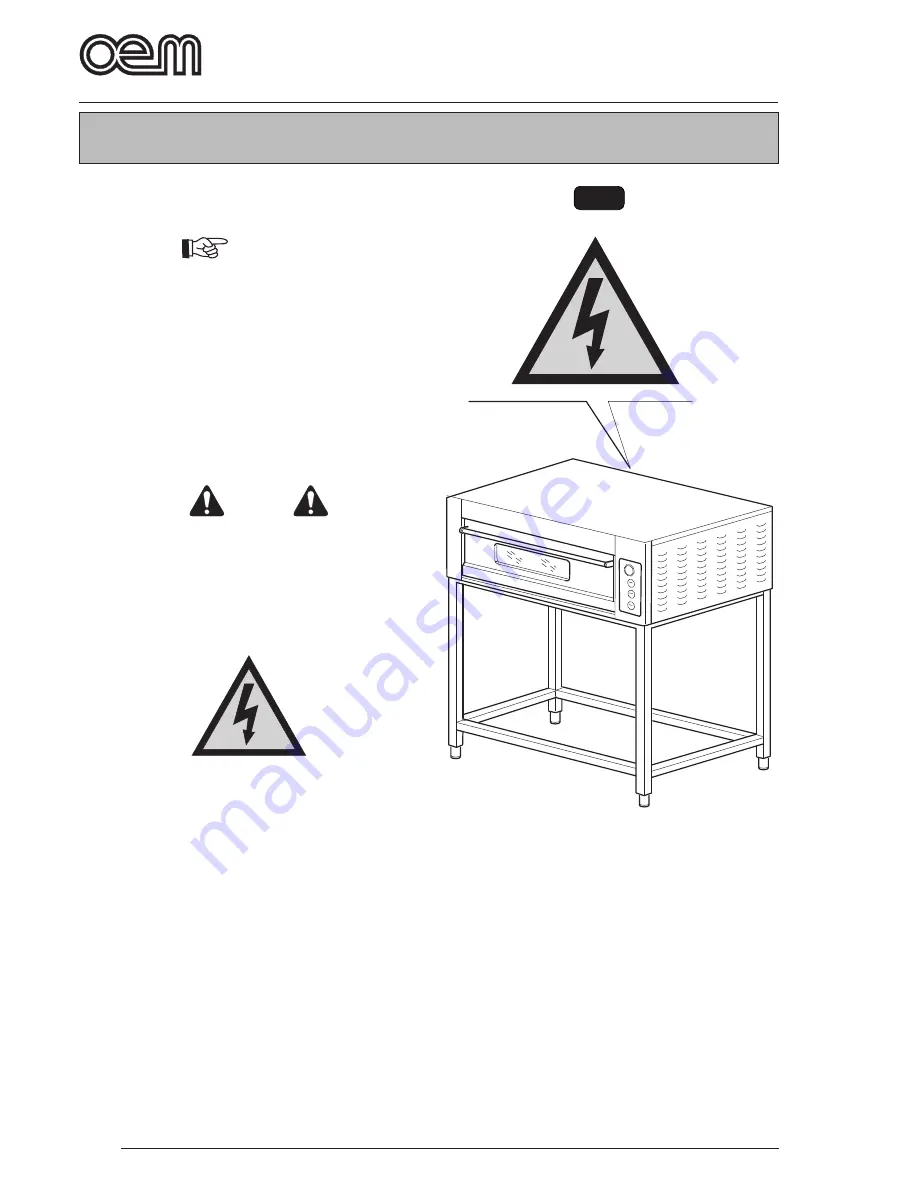

FIG. 1

4.1 - TYPE OF USE AND CONTRAINDICA-

TIONS

IMPORTANT

DOMITOR DM/DB ovens are professional machines

suitable for baking pizza and similar products.

The various models shall only be used to process

as above; in case of any other use, manufacturer

disclaims all responsibility for accidents to persons

or objects and customer will be debarred from a

possible guarantee right.

4.2 - SAFETY PLATES (Fig. 1)

The warning plates with explanatory symbols are to

be found in all those areas that may be dangerous for

operators or engineers.

DANGER

On the oven, there are plates reporting safety

instructions which shall absolutely be followed

by any oven user. Manufacturer disclaims all

responsibility in case of accidents to persons

or objects arising from a non-fulfi lment of such

instructions.

Danger: machine under voltage

• Do not work with the machine under voltage.

Chapter 4

Summary of Contents for DOMITOR

Page 1: ...Installation and Operation Manual PIZZA OVEN DOMITOR...

Page 2: ......

Page 4: ......

Page 42: ......