7

Table 2

SPEED SELECTION

Before changing speeds, the mixer must always be STOPPED first

. The necessary speed can then be

selected before restarting the machine by pressing the Green Start Button.

The speed selected depends largely on the quantity and consistency of the product. It is recommended

that mixing is always started at the lowest speed and progressively increased to the desired setting. In an

emergency situation always use the Red Emergency Stop Button to stop the machine.

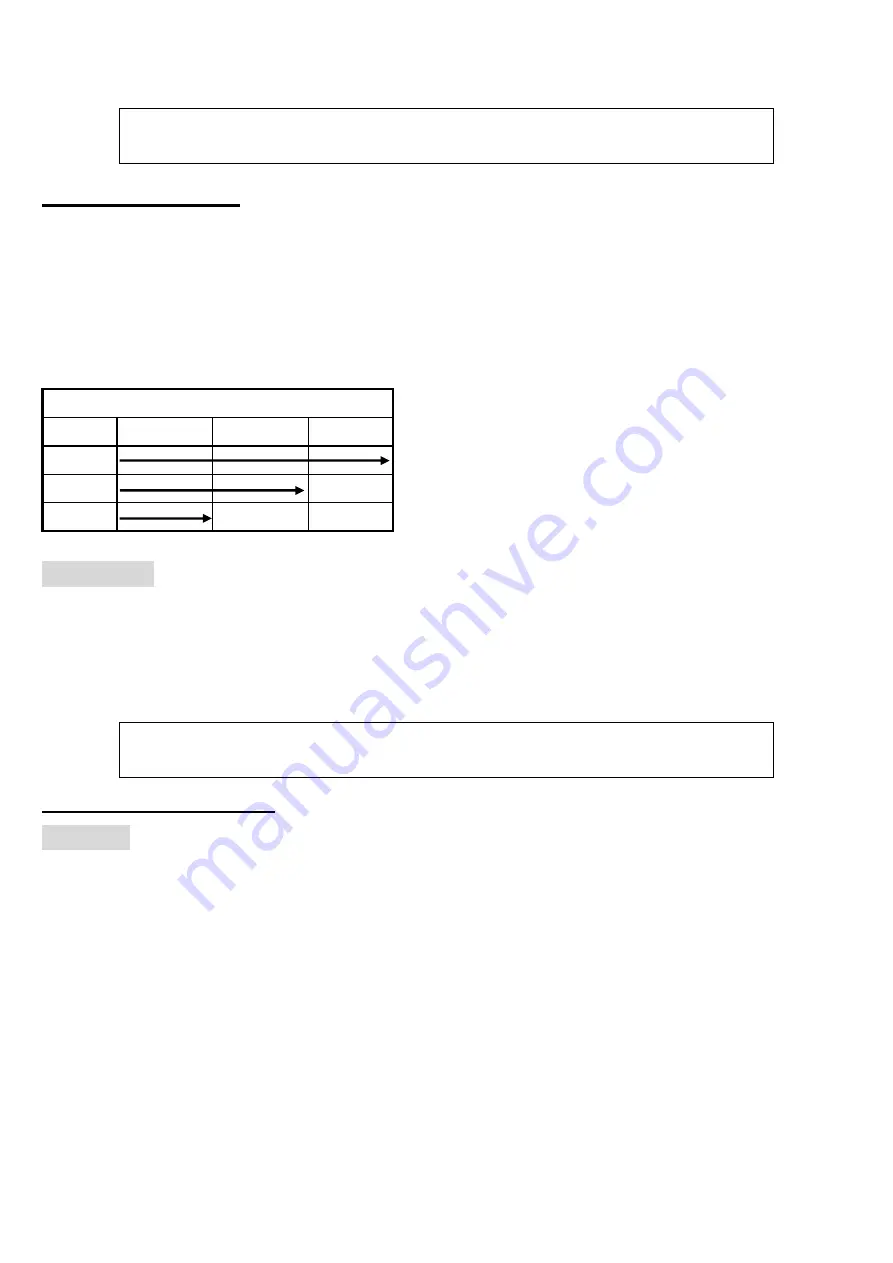

Table 2

shows the

recommended speeds for the range of tools.

IMPORTANT:

When mixing products always follow the recommended agitator and speed setting.

The mixer is equipped with a motor overload protection. If the mixer shuts off during operation, reduce

the batch size and

wait 2 minutes

.

Press the stop button then press the start button.

For heavier loads, the mixer should not run longer than 15 minutes without pausing for a cool down

period of at last 15 minutes or more before resuming mixer. For lighter loads the mixer should not run longer

than 30 minutes without pausing for a cool down period of at last 30 minutes or more before resuming

mixer.

Cleaning Instructions

CARE OF YOUR MIXER

CAUTION:

ALWAYS DISCONNECT OR UNPLUG THE ELECTRICAL POWER FROM THE MIXER BEFORE

CLEANING.

The mixer is designed for simple maintenance carried out by operators. It may be necessary from time

to time to apply a little Vaseline and oil to the rods on which the bowl cradle slides. If so, use a little food

quality lubricant, ensuring that there is no excess oil that could contaminate the food mix.

Clean the mixer thoroughly after use. After isolating the machine from the electricity supply, the body

should be wiped down with a damp cloth.

Do not spray the machine with or immerse it in water

. Do not

forget to clean the rear of the machine and

do not allow the rear vents to become blocked as this may

result in overheating

.

Pay particular attention to the bowl pins and any surrounding areas of the cradle to prevent the

accumulation of mix, as this could prevent correct location of the bowl. For the same reason ensure that the

beater shaft and each of the sockets on the tools are cleaned thoroughly. The bowl and tools should be

washed in hot soapy water, rinsed and dried before being put into storage.

Do not wash the agitator s in a

dishwasher, as the polished finish will be adversely affected by the dishwashing chemicals.

Operating Instructions

Recommended speed

1

st

Speed 2

nd

Speed 3

rd

Speed

Whisk

Beater

Hook